Classification£º¡¡Pneumatic butterfly valve

Product Name£º¡¡Wafer Pneumatic Metal Seal Butterfly Valve

Product Description£º

Wafer Pneumatic Metal Seal Butterfly Valve adopts a "U" type stainless steel seal ring, and this precision elastic seal ring and the 3D eccentric polishing disc contact each other to solve the problem that the seal surface is still in the sliding contact friction when the traditional eccentric butterfly valve opened and closed from 0 ° to 10 ° in a twinkle, which realizes the seal surface separating when the disc opened in a twinkle and seal recovery when the disc closed, and which also achieves the purpose of the best seal performance and prolonged service life. Hence, this valve is widely suited to the pipeline of medium temperature ≤ 550 ¡æ, as the best device to regulate the flow and cut off fluid, which is applied in the fields of metallurgy, electric power, petroleum, chemical, air, gas, combustible gas and water supply and drainage and other corrosive medium.

As a device to regulate flow, pressure, temperature and proportion, , wafer type pneumatic metal seal butterfly valve is suited to various middle &low-voltage and the powder or liquid medium services.

¡ïHigh temperature resistance, good seal performance, zero leakage.

Metal sealed pneumatic butterfly valves support the structure of 3D eccentric metal sealed, whose seal mode is metal-to-metal, also can be changed into the other seal modes such as the metal seal ring to the metal, and the stainless steel plate seal ring or the graphite composite plate seal ring to the metal.

In the situation of the high temperature and high pressure, this series valves with U type stainless steel seal ring still hold stable seal performance and elasticity, whose special seal system guarantees the higher seal performance under temperature range from ultra low temperature to ultra high temperature.

3D eccentric seal system and ergonomic design make the valves have a small opening resistance.

The seal surface of the disc presents a convex cone shape. When the valve is opening, the every contact around the disc departs from the seal ring at the same time, and the solids are hardly accumulated on the seal surface.

The process of shutting off the valve is realized by the compression control of elastic seal ring.

Without jam between disc and seal ring, seal performance is not affected by temperature changes.

The sealing of the stem axis is realized by graphite-compacted seal ring, which assures zero leakage during the whole fire accident process. Hence, this kind of valve is called the nature valve of fire safety.

The valve adopts the advanced structure of 3D eccentric metal composite cone canting, and can reach up to zero leakage.

The series valves with rubber seal hold the excellent seal performance between the disc and seat when it shut off, good two-way seal performance, small torque, and the series valves ensure zero leakage under the operating pressure.

There is almost no friction between the disc and seat due to its 3D eccentric structure, moreover, the series have the closer seal performance, the further being shut off.

¡ïSmall opening torque, no frictional rotation, long service life

The valve is operated by the working principle that the shaft drive the disc to rotate 90 degrees to realize flexible switch without jam, jumpiness, and the torque is small.

More than 50,000 operation life without fault, keep your system operating safely and reliably.

¡ïSmall volume, light weight, quick switch

The valve is comprised of body, disc, shaft, seat and gears, which has simple and compact structure, light weight, convenience in transportation, installation, and disassembly.

Switch with 90 degree has the advantages of quick switch, small torque, saving energy.

The valve has excellent modulation performance, and whose flow characteristic is approximate to linearity.

¡ïReplacing the body material, the different seal ring is suitable for different medium.

With the whole baking finish surfaces, the valve can effectively prevent rusting, and is suited to different medium by changing better seal rings or seal materials.

The body has high cost-effective, especially large diameter butterfly valve (prefer to butterfly valve in the occasions of middle and low pressure), and is configured with a convex pipe flanges.

Superior cost-effective performance makes the butterfly valves have a broad scope of application.

¡ïThe pneumatic actuator owns excellent performance.

Using the new GT series of pneumatic actuators, this valve has a double acting and spring return (spring reset) to realize gear driving safely and reliably. Large diameter valves adopts AW series pneumatic actuator to realize fork transmission, which has reasonable structure, large output torque, a double acting and spring return.

1. The gear type double cylinder has large output torque and small volume.

2. The cylinder is made of aluminum alloy with the light weight, beautiful appearance.

3. The manual handle can be installed at the top and bottom of valve.

4. The rack type connection can regulate opening angle and rated flow.

5. The actuator can achieve automatic operation when equipped with electrical signal feedback indication and all kinds of accessories.

6. The standard connection ISO05211 provided the convenient installation and replacement for product.

7. Both-sides adjustable screw can make the standard products have ±4° adjustable range at the angle of 0 ° and 90 ° to ensure the synchronous precision with the valve.

Body ratings: PN1.0/PN1.6Mpa/PN2.5Mpa

Valve size: DN50-DN1200

Sealed material: Alloy seal

Flow characteristics: approximate EQ%.

Stem seal: NBR, HNBR, PTFE, Graphite

Body material: WCB/SUS304/SUS316L/CF8/CF8L Stainless steel

Stem material: WCB/SUS304/SUS316L/CF8/CF8L Stainless steel

Body connections: Wafer/flange

Operating pressure: PN1.6Mpa, PN2.5Mpa

Medium Temp. ≤540¡æ

The compliance standards of the products

Design standards: GB/T12238-1989

Flange connection size: GB/T9113.1-2000, GB/T9113.2-2000, GB/T9115.1-2000, GB/T9115.2-2000

Structure length: GB/T12221-1989Pressure test: GB/T13927-1992, JB/T9092-1999

Optional accessories

Please select the accessories according to the different control and requirement.

Accessories to cut off: Single electric control solenoid valve, double electric control solenoid valve, the signal feedback device of limited switch

Modulation type accessories: The electrical positioner, pneumatic positioner, electrical converter

Air source treatment accessories: Air-set, air source treatment triplet

Manual handle: HVSD manual operation.

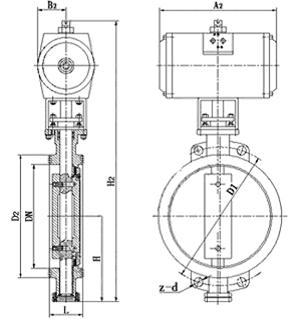

Installation size drawing

The properties specification

| Valve size | 50 ~1200 | 50 ~600 | mm | ||||||

| Body ratings PN | 0.6 | 1 | 1.6 | 150LB | 2.5 | 4 | 300LB | Mpa | |

| Test properties pressure | Seal | 0.66 | 1.1 | 1.76 | 2.2 | 2.75 | 4.4 | 5.5 | |

| Body | 0.9 | 1.5 | 2.4 | 3 | 3.75 | 6 | 7.5 | ||

| Applicable Temp. | ≤540 | ¡æ | |||||||

| Applicable medium | Water, oil, gas, all kinds medium of high temperature or containing impurities | ¡¡ | |||||||

The material of the main parts

| No. | Part name | Material name |

| 1 | Body | Carbon steel, CF8 Stainless steel, CF8M Stainless steel,CF3M Stainless steel |

| 2 | Disc | Carbon steel, CF8 Stainless steel, Cram Stainless steel, CF3M Stainless steel |

| 3 | Rotatable shaft | 2Cr13, 304 Stainless steel,316 Stainless steel,316L Stainless steel |

| 4 | Disc seal ring | All kinds of stainless steel complexes |

| 5 | Shaft guard | ZCuZn38Mn2Pb2, stainless steel complexes with PTFE |

| 6 | Packing | Grafoil |

The pressure and temperature range

| The highest temperature¡æ |

≤20 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 425 | 450 | 475 | 500 | Body material | |

| Body ratings Mpa |

||||||||||||||

| 0.6 | 0.6 | 0.6 | 0.54 | 0.48 | 0.42 | 0.36 | 0.3 | 0.21 | ---- | ---- | ---- | ---- | Stainless steel | |

| 1.0 | 1 | 1 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 | 0.35 | ---- | ---- | ---- | ---- | ||

| 1.6 | 1.6 | 1.6 | 1.44 | 1.28 | 1.12 | 0.96 | 0.8 | 0.56 | ---- | ---- | ---- | ---- | ||

| 2.5 | 2.5 | 2.5 | 2.25 | 2 | 1.75 | 1.5 | 1.25 | 0.88 | ---- | ---- | ---- | ---- | ||

| 0.6 | 0.57 | 0.52 | 0.48 | 0.45 | 0.42 | 0.4 | 0.38 | 0.37 | 0.36 | 0.35 | 0.35 | 0.35 | Carbon steel | |

| 1.0 | 0.95 | 0.86 | 0.81 | 0.76 | 0.71 | 0.66 | 0.63 | 0.61 | 0.6 | 0.59 | 0.58 | 0.58 | ||

| 1.6 | 1.52 | 1.31 | 1.29 | 1.21 | 1.13 | 1.06 | 1.01 | 0.98 | 0.96 | 0.94 | 0.93 | 0.92 | ||

| 2.5 | 2.38 | 2.15 | 2.01 | 1.89 | 1.77 | 1.66 | 1.59 | 1.53 | 1.5 | 1.48 | 1.46 | 1.45 | ||

The installation size of wafer type

|

Valve size |

Structure length standard value |

Figure size£¨reference value£© |

Connection size(Standard value) |

Weight(kg) |

|||||||

|

H |

H2 |

A2 |

B2 |

PN1.6MPa |

PN2.5MPa |

||||||

|

mm |

inch |

L |

D1 |

Z-d |

D1 |

Z-d |

|||||

|

50 |

2 |

43 |

112 |

625 |

245 |

72 |

125 |

4-14 |

125 |

4-18 |

11 |

|

65 |

21/2 |

46 |

115 |

625 |

245 |

72 |

145 |

4-14 |

145 |

8-18 |

12 |

|

80 |

3 |

49 |

120 |

645 |

245 |

72 |

160 |

8-18 |

160 |

8-18 |

15 |

|

100 |

4 |

56 |

138 |

675 |

355 |

92 |

180 |

8-18 |

190 |

8-22 |

17 |

|

125 |

5 |

64 |

164 |

715 |

355 |

92 |

210 |

8-18 |

220 |

8-26 |

27 |

|

150 |

6 |

70 |

175 |

800 |

355 |

92 |

240 |

8-22 |

250 |

8-26 |

29 |

|

200 |

8 |

71 |

208 |

850 |

250 |

170 |

295 |

12-22 |

310 |

12-26 |

45 |

|

250 |

10 |

76 |

243 |

925 |

250 |

170 |

355 |

12-26 |

370 |

12-30 |

69 |

|

300 |

12 |

83 |

283 |

1035 |

450 |

220 |

410 |

12-26 |

430 |

16-30 |

86 |

|

350 |

14 |

92 |

310 |

1070 |

450 |

220 |

470 |

16-26 |

490 |

16-33 |

122 |

|

400 |

16 |

102 |

340 |

1190 |

450 |

220 |

525 |

16-30 |

550 |

16-36 |

141 |

|

450 |

18 |

114 |

380 |

1250 |

650 |

280 |

585 |

20-30 |

600 |

20-36 |

191 |

|

500 |

20 |

127 |

410 |

1290 |

650 |

280 |

650 |

20-33 |

660 |

20-36 |

260 |

|

600 |

24 |

154 |

470 |

1455 |

850 |

380 |

770 |

20-36 |

770 |

20-39 |

380 |

|

700 |

28 |

165 |

550 |

1585 |

850 |

380 |

840 |

24-36 |

875 |

24-42 |

450 |

|

800 |

32 |

190 |

640 |

1700 |

1250 |

380 |

950 |

24-39 |

990 |

24-48 |

650 |

|

900 |

36 |

203 |

710 |

1865 |

1250 |

380 |

1050 |

28-39 |

1090 |

28-48 |

830 |

|

1000 |

40 |

216 |

770 |

2015 |

1250 |

380 |

1170 |

28-42 |

1210 |

28-56 |

1050 |

|

1200 |

48 |

254 |

890 |

2250 |

1250 |

380 |

1390 |

32-48 |

1420 |

32-56 |

1400 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...