Classification£º¡¡Electric control valve

Product Name£º¡¡Tiny Flow Electric Control valve

Product Description£º

Tiny flow control valve can control the operation by inputting control signal and single phase power to satisfy various regulating needs for tiny flow in pressure, flow, temperature, and the level of liquid etc. This valve is especially suitable for the various fields of tiny flow and high precision control.

¡ïDesign for high temperature resistance

The valve with high performance and metal seal adopts partial stellite seal ring to realize high temperature resistance for 350 ¡æ.

The unique body structure with long stem can effectively increase the distance between the actuator and high temperature medium, which has a better heat dissipation performance.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïPatent for tiny flow control technology

The unique patent technology for the plug design is especially suitable for the various fields of the tiny flow regulation and control.

The patent technology for tiny flow control: the tiny flow ≤ 1m³/h(gas), 1t/h£¨liquid£©

Patent No.£ºZL201020225917.9

¡ïHigh precision, Small gyration error

Unique integrated structure for the stem and plug can effectively solve the problem of mechanical gyration error. The gyration error is less than 0.5%.

¡ïAllowing a great pressure drops

The pressure drops resistance reaches more than 1.0MPa

¡ïThe valve owns a self-cleaning function to effectively guarantee the piping circulating.

The scissors opening between the valve seat and the trim can easily cut off all kinds of impurities in the pipeline to effectively guarantee the pipeline circulating.

¡ïGood seal performance

The Innovative & improved metal seal valve has the sealed surface of flange without screw hole to enhance the sealing strength, which can effectively avoid the danger of surface leakage for the metal sealed valve’s flange surface, the sealing level is grade V.

¡ïErosion resistance, design for free maintenance

The valve has the advantages such as straight-through structure, simple channel, small flow resistance, erosion resistance and no jam.

The valve never needs maintenance from the beginning of first operation, which effectively saves the maintenance cost.

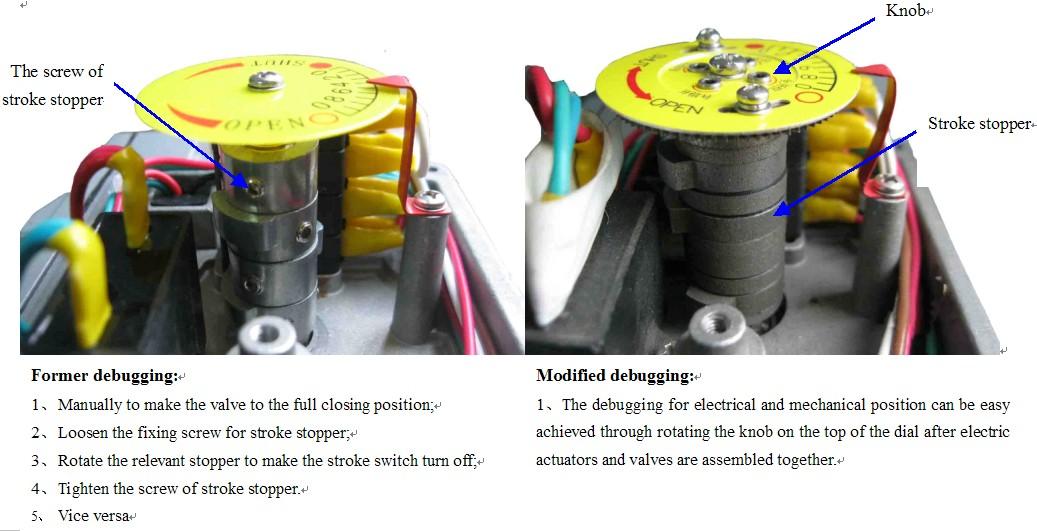

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

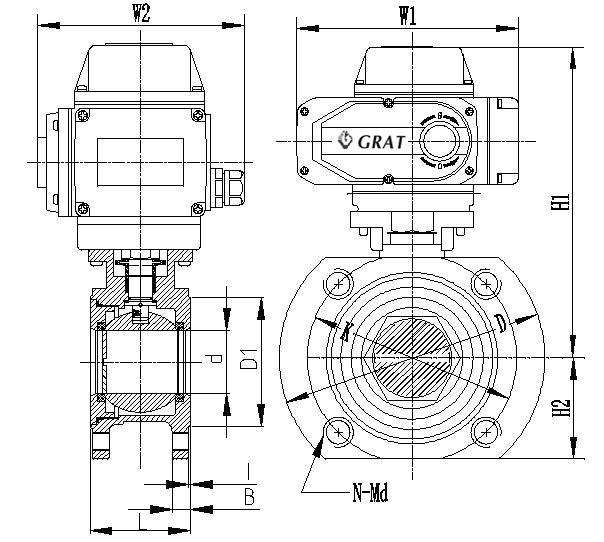

Valve size: DN15-DN250

Body ratings: PN1.6MPa

Body connections: Wafer£¬Flange

Seat type: Stainless steel moveable metal seal¡¢PTFE soft seal

Action time: 30 S£¨0-90°£©

Power supply: AC220V

Control signal: 4¡«20mA 0¡«5V

Output signal: 4¡«20mA 0¡«5V

Operating pressure: PN1.6Mpa PN2.5Mpa

Medium Temp. ≤350¡æ

Ambient Temp. ≤50¡æ

Flow coefficient£¨CV£©: Please download the data on our website for reference¡£(Custom flow coefficient depends on the customer’s requirement.) Applicable medium: Mine pulp, coal pulp, paper pulp, water, oil, gas.

Dead zone: 0.5%

Repetition error: 0.5%

Body material: SUS304 SUS316 WCB

|

DN |

L |

D |

K |

D1 |

N-Md |

B |

I |

H1 |

H2 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

||||||||||||

|

15 |

1/2″ |

35 |

95 |

65 |

46 |

4-φM12 |

9 |

2 |

234 |

196 |

145 |

196 |

5.6 |

|

20 |

3/4″ |

38 |

100 |

75 |

56 |

4-φM12 |

12 |

2 |

242 |

196 |

145 |

196 |

6 |

|

25 |

1″ |

42 |

110 |

85 |

66 |

4-φM12 |

12.7 |

2 |

218 |

196 |

145 |

196 |

5.8 |

|

32 |

11/4″ |

52 |

133 |

100 |

78 |

4-φM16 |

14 |

3 |

231 |

196 |

145 |

196 |

6.7 |

|

40 |

11/2 |

61 |

145 |

110 |

87 |

4-φM16 |

15 |

3 |

238 |

196 |

145 |

196 |

7.6 |

|

50 |

2 |

73 |

160 |

125 |

99 |

4-φM16 |

16.7 |

3 |

251 |

196 |

145 |

196 |

8.7 |

|

DN (mm) |

A |

φd |

H1 |

H2 |

H |

F |

Weight Kg |

|

15 |

62 |

54 |

74 |

75 |

390 |

210 |

6.9 |

|

20 |

62 |

54 |

74 |

75 |

390 |

210 |

7.1 |

|

25 |

62 |

54 |

74 |

75 |

390 |

210 |

7.3 |

|

32 |

62 |

78 |

80 |

75 |

400 |

210 |

7.5 |

|

40 |

62 |

82 |

85 |

75 |

405 |

210 |

7.7 |

|

50 |

75 |

100 |

87 |

95 |

430 |

210 |

8.9 |

|

Valve size:DN |

D |

G |

L |

H1 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

|||||||

|

8 |

1/2″ |

8 |

14.3 |

65 |

177 |

196 |

145 |

5.0 |

|

10 |

3/4″ |

10 |

18 |

65 |

177 |

196 |

145 |

5.2 |

|

15 |

1″ |

15 |

22 |

72 |

188 |

196 |

145 |

5.3 |

|

20 |

11/4″ |

18 |

28 |

85 |

190 |

196 |

145 |

5.5 |

|

25 |

11/2 |

24 |

34.5 |

91 |

200 |

196 |

145 |

5.3 |

|

32 |

2 |

30 |

43.5 |

110 |

205 |

196 |

145 |

5.9 |

|

40 |

1/2″ |

38 |

49.5 |

122 |

212 |

196 |

145 |

6.2 |

|

50 |

3/4″ |

48 |

62 |

145 |

220 |

196 |

145 |

7.2 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...