Classification£º¡¡Electric control valve

Product Name£º¡¡Metal Seat Electric Flow Control Valve

Product Description£º

With high temperature resistance, corrosion resistance and high control precision, EV series electric flow control valve specially is best suited to the situation of no air supply, all kinds of mediums with self-cleaning and abrasion resistance such as mine pulp and paper pulp, which meets technical parameters by regulating and controlling the flow in various special technologic areas.

¡ïThe flow modulation characteristics

Unique V type structure for the trim solves the control stability problem of traditional ball valve. For the stability of flow regulation and the percentage properties, make the opening degree between the control object and the valve tend to linearity. When the valve opens, the flow increases very slowly. The trim type determines the valve properties, so different opening type of trim , and so the same diameter of the valve has different CV values and flow properties.

¡ïDesign for high temperature resistance

The valve with high performance and metal seal adopts partial stellite seal ring to realize high temperature resistance for 350 ¡æ.

The unique body structure with long stem can effectively increase the distance between the actuator and high temperature medium, which has a better heat dissipation performance.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïHigh precision, Small gyration error

Unique integrated structure for the stem and plug can effectively solve the problem of mechanical gyration error.

The gyration error is less than 0.5%

¡ïAllowing a large pressure drops

The pressure drops resistance reaches more than 1.0Mpa.

¡ïThe valve owns a self-cleaning function to effectively guarantee the piping circulating.

The scissors opening between the valve seat and the trim can easily cut off all kinds of impurities in the pipeline to guarantee the pipeline circulating.

¡ïGood seal performance

The Innovative & improved metal seal valve has the sealed surface of flange without screw hole to enhance the sealing strength, which can effectively avoid the danger of surface leakage for the metal sealed valve’s flange surface, the sealing level is grade V.

¡ïErosion resistance, design for free maintenance

The valve has the advantages such as straight-through structure, simple channel, small flow resistance, no jam ,and erosion resistance.

The valve never needs maintenance from the beginning of first operation, which effectively saves the maintenance cost.

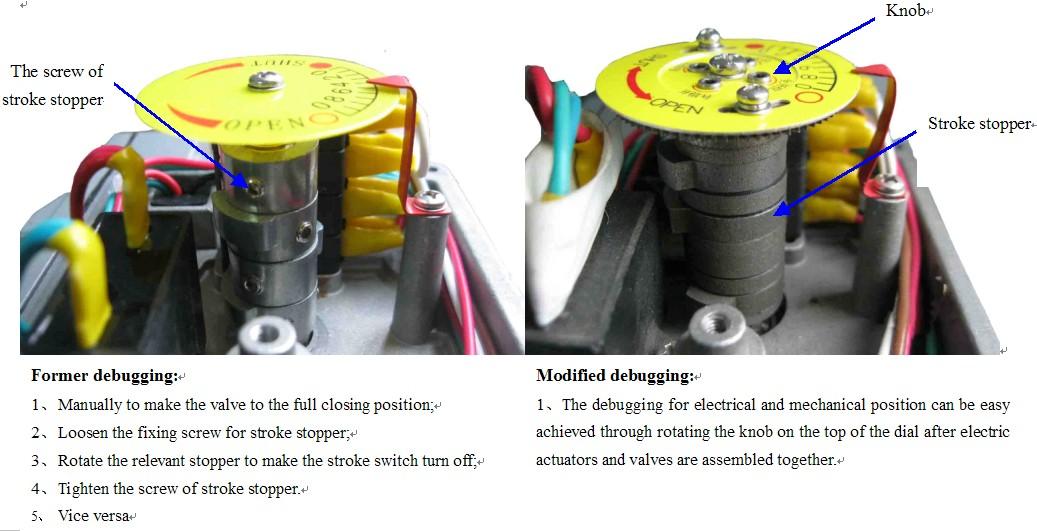

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Body size: DN15-DN250 (Please contact us for the detailed data of the larger size valve.£©

Body ratings: PN1.6MPa

Body connections: Wafer, flange

Seat type: Stainless steel moveable metal seal¡¢PTFE Soft seal

Body material: SUS304 SUS316 WCB

Plug material: SUS304 SUS316 WCB

Action time: 30S£¨0-90°£©

Power supply: AC220V

Control signal: 4¡«20mA 0¡«5V

Output signal: 4¡«20mA 0¡«5V

Operating pressure: PN1.6Mpa PN2.5Mpa

Medium Temp. ≤350¡æ

Ambient Temp. ≤50¡æ

Flow coefficient£¨CV£©: Please download the data on our website for reference¡£(Custom flow coefficient depends on the customer’s requirement.) Applicable medium: Mine pulp, coal pulp, paper pulp, water, oil, gas.

Dear zone: 0.5%

Repeatability error: 0.5%

|

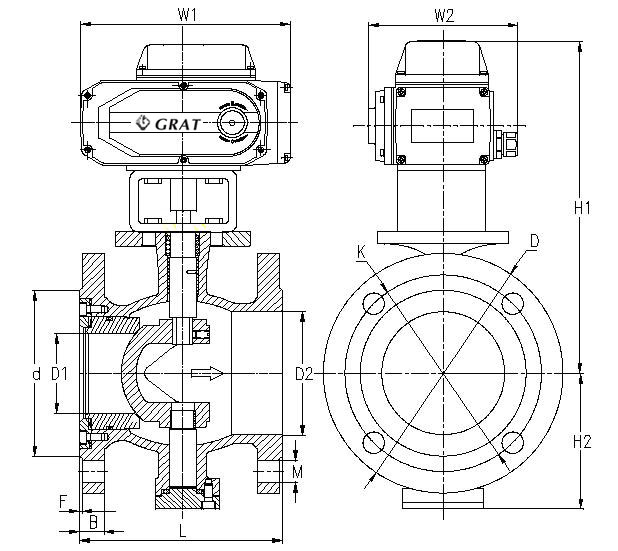

DN(mm) |

D1 |

D2 |

d |

K |

D |

M |

B |

F |

L |

H1 |

H2 |

W1 |

W2 |

Weight |

|

15 |

15 |

28 |

45 |

65 |

95 |

4-Φ14 |

14 |

2 |

102 |

290 |

55 |

196 |

145 |

¡¡ |

|

20 |

15 |

28 |

55 |

75 |

105 |

4-Φ14 |

14 |

2 |

102 |

300 |

60 |

196 |

145 |

¡¡ |

|

25 |

20 |

40 |

66 |

85 |

115 |

4-Φ14 |

14 |

2 |

102 |

310 |

65 |

196 |

145 |

¡¡ |

|

32 |

25 |

46 |

78 |

100 |

135 |

4-Φ18 |

16 |

2 |

114 |

320 |

75 |

196 |

145 |

¡¡ |

|

40 |

32 |

54 |

85 |

110 |

145 |

4-Φ18 |

16 |

2 |

114 |

330 |

80 |

196 |

145 |

¡¡ |

|

50 |

40 |

65 |

100 |

125 |

160 |

4-Φ18 |

16 |

2 |

124 |

340 |

85 |

196 |

145 |

¡¡ |

|

65 |

50 |

80 |

120 |

145 |

180 |

4-Φ18 |

18 |

2 |

145 |

350 |

100 |

196 |

145 |

¡¡ |

|

80 |

65 |

100 |

135 |

160 |

195 |

8-Φ18 |

20 |

2 |

165 |

360 |

105 |

196 |

145 |

¡¡ |

|

100 |

80 |

110 |

155 |

180 |

215 |

8-Φ18 |

20 |

2 |

194 |

420 |

115 |

196 |

145 |

¡¡ |

|

125 |

100 |

135 |

185 |

210 |

245 |

8-Φ18 |

22 |

3 |

210 |

430 |

130 |

255 |

184 |

¡¡ |

|

150 |

125 |

165 |

210 |

240 |

280 |

8-Φ23 |

24 |

3 |

229 |

450 |

150 |

255 |

184 |

¡¡ |

|

200 |

160 |

205 |

265 |

295 |

335 |

12-Φ23 |

26 |

3 |

243 |

480 |

175 |

255 |

184 |

¡¡ |

|

250 |

210 |

260 |

320 |

355 |

405 |

12-Φ26 |

30 |

3 |

297 |

520 |

220 |

255 |

184 |

¡¡ |

|

300 |

250 |

322 |

375 |

410 |

460 |

12-Φ26 |

30 |

3 |

340 |

600 |

250 |

255 |

184 |

¡¡ |

|

350 |

300 |

365 |

435 |

470 |

520 |

16-Φ26 |

34 |

3 |

422 |

630 |

280 |

255 |

184 |

¡¡ |

|

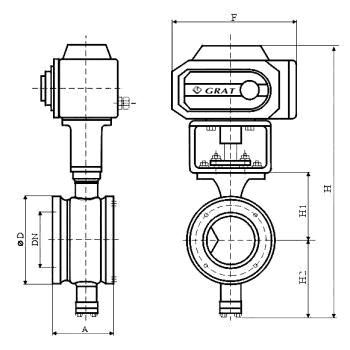

DN(mm) |

A |

φd |

H1 |

H2 |

H |

F |

Weight Kg |

|

15 |

62 |

54 |

74 |

75 |

390 |

210 |

6.9 |

|

20 |

62 |

54 |

74 |

75 |

390 |

210 |

7.1 |

|

25 |

62 |

54 |

74 |

75 |

390 |

210 |

7.3 |

|

32 |

62 |

78 |

80 |

75 |

400 |

210 |

7.5 |

|

40 |

62 |

82 |

85 |

75 |

405 |

210 |

7.7 |

|

50 |

75 |

100 |

87 |

95 |

430 |

210 |

|

|

65 |

80 |

120 |

105 |

115 |

460 |

210 |

|

|

80 |

100 |

131 |

115 |

125 |

520 |

270 |

|

|

100 |

115 |

158 |

125 |

125 |

530 |

270 |

|

|

125 |

130 |

180 |

140 |

155 |

570 |

270 |

|

|

150 |

160 |

216 |

153 |

165 |

600 |

270 |

|

|

200 |

200 |

260 |

200 |

195 |

680 |

270 |

|

|

250 |

240 |

325 |

225 |

225 |

730 |

270 |

|

Maximum allowable leakage

|

Valve size (mm) |

Metal seat |

Soft seat |

|

15 |

1.1ml/min |

0.12ml/min |

|

20 |

1.5ml/min |

0.16ml/min |

|

25 |

2.0ml/min |

0.20ml/min |

|

32 |

2.4ml/min |

0.24ml/min |

|

40 |

3.0ml/min |

0.30ml/min |

|

50 |

3.8ml/min |

0.38ml/min |

|

65 |

5.2ml/min |

0.52ml/min |

|

80 |

6.2ml/min |

0.62ml/min |

|

100 |

7.6ml/min |

0.76ml/min |

|

125 |

9.6ml/min |

0.96ml/min |

|

150 |

12.0ml/min |

1.20ml/min |

|

200 |

15.4ml/min |

1.54ml/min |

|

250 |

19.2ml/min |

1.92ml/min |

The material of the standard structure

|

Part name |

Material |

|

Body |

Carbon steel ASTM A216 WCC |

|

Lining |

High chrome steel ASTM A532 grade type A |

|

“V” ball |

High chrome steel ASTM A532 grade ¢ó type A |

|

Seal ring |

High chrome steel ASTM A532 grade ¢ó type A |

|

fixed Seal ring |

Carbon steel ASTM A105 |

|

Bearing guard |

High chrome steel ASTM A532 grade ¢ó type A |

|

Bearing |

44oC58Rc |

|

Drive shaft |

17-4PH Cond.H1025 |

|

Driven shaft |

17-4PH Cond.H1025 |

|

Pin |

Carbon steel£¬ zincification |

|

Gasket |

graphite stainless steel wire |

|

Packing |

PTFE£¬filling carbon |

|

Stuffing box ring and guard |

316 SST |

|

Bolt |

SA-193-B7 |

|

Nut |

SA-194-2H |

|

Fixed ring bolt and lock |

316 SST |

|

Seal ring lining£¨optional£© |

PSZ Ceramic |

|

“V” ball£¨optional£© |

PSZ Ceramic |

The implementation standards of the electric control valve

|

Manufacturing standards |

GB/T 122387-89 |

|

Flange standards |

GB9113-2000¡¢GB17241.6-1998 |

|

Structure length standards |

GB12221-89 |

|

Inspection standards |

GB/T 13927-92 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...