Classification£º¡¡Electric butterfly valve

Product Name£º¡¡Gas Low-load Electric Butterfly Valve

Product Description£º

As a gas modulation device & a two-way switch device, 600S gas low-load electric butterfly valve is suitable to ventilation and dust removing pipeline in the industrial fields of metallurgy, mineral, cement, chemical-engineering, power generation, industrial furnace and so on.

¡ïSmall opening force-torque, free-friction rotation, long service life

The seal performance for two-ways between the disc and the seat is superior when closed.

The friction between the disc and the seat is small.

The operation is realized by the working principle that the shaft drives the disc to rotate 90 ° to realize flexible switch without jam, jumpiness.

More than 50,000 operation life without fault, keep your system operating safely and reliably.

Without connecting rod and bolts inside, the valve has reliable operation, long service life, which is easy to install in any direction, and not affected by the medium flow.

¡ïSimple structure, easy operation, high cost- effective.

The valve welded by the steel plate is simple& short structure, light weight, and is convenient to use and maintain, which is equipped with electronic whole actuator to easily realize on-site operation and remote control.

With a welded structure between central line disc and steel plate, the valve has compact structure, light weight, convenient installation, small flow resistance, large flow capability, easy operation, and can avoid the influence of high temperature expansion.

Electric ventilation butterfly valve is welded by steel plate with short size structure, light weight, convenient installation, small driving torque, flexible switch and convenient operation.

Be equipped with seal ring, the body has small leakage because there is no visible interstices between the sealed parts.

The large expansion interstices between disc and body can effectively avoid the blockade caused by expanding with heat and contracting with cold.

The switch type electric actuator and the stem have been connected and debugged well,then the disc of metal sealed butterfly valve is driven by the electric energy to realize the 90 ° rotation.

The valve is controlled accurately via switch signal from industrial automation control system, which regulates and controls the different technic parameters of the flow, temperature and pressure.

¡ïLinearity flow characteristics£¬Excellent regulated performance, wide application industries range.

The flow characteristics is approximate to EQ%, and the same body can afford two kinds of function choices including switch action and modulation action.Low-load electric butterfly valve (ventilation butterfly valve) is widely applied in the fields of metallurgy, petroleum and chemical, electric power, building materials industry, mining and so on£¬which regulates and controls the medium gas of the industrial piping.

Configured with a convex pipe flanges, the body has high cost-effective, especially large diameter butterfly valve (prefer to butterfly valve in the occasions of middle and low pressure), the butterfly valves have superior cost-effective performance to realize a broad scope of applications.

¡ïThe patent positioning technology

PPD positioning technology completely solves the difficult application problem including poor positioning accuracy and long time reliable operation.

¡ïVarious solutions for seal form

Seal form: open seat, back-seated seat (ultra high temperature application), sealed oblique plate seat (room temperature application).

The body is unsealed.

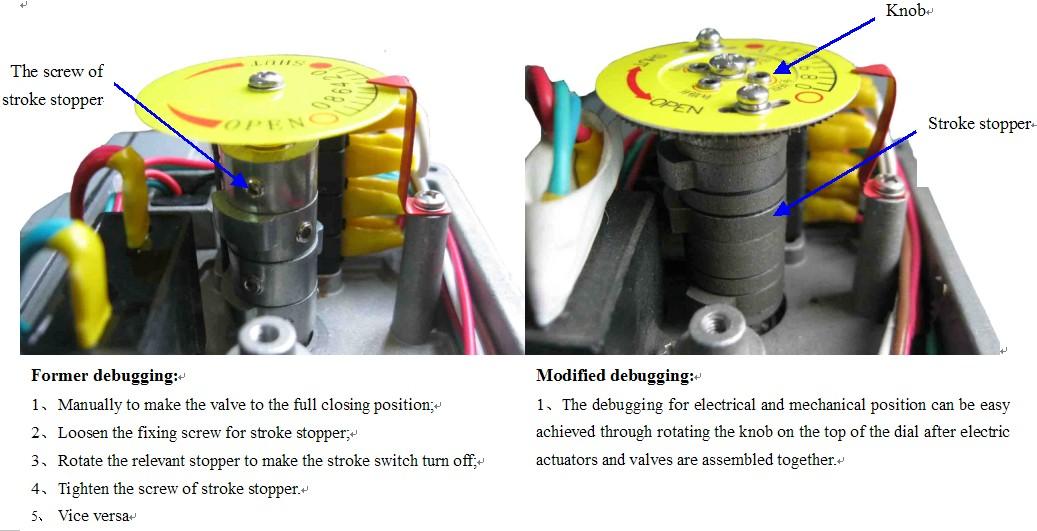

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Power supply£ºAC220V 50/60HZ

Operating temperature£º0-450¡æ£¨Optional£©

Imput signal£º4-20mA

Output signal£º4-20mA

Body connections£ºWafer /Flange£¨Optional£©

Flow characteristics£º approximate EQ%

Body material£º A3 Steel, Heat-resistance steel

Disc material£ºA3, Heat-resistant steel,SUS304 Stainless steel,SUS316 Stainless steel

Seal type£ºopen type, back-seated type (ultra high temperature application), sealed oblique plate type (room temperature application).

Valve size£ºDN100¡«DN2000¡¡¡¡

Body ratings£º0.1¡«0.6MPa¡¡¡¡

Test pressure£º Sealed 0.15Mpa£» Body 0.11Mpa¡¡¡¡

Applicable temperature£¼200¡æ¡¡Special£º£¼450¡æ¡¡

Applicable medium£ºSmoke,air,gas.

The compliance standards of the product

Manufacturing standards£ºJB/T8692-1998

Design standards: GB/T122381989¡¢API609

Check and test: GB/T139271992¡¢API598

Side flange connections: GB9115.88¡¢GB9113.3 ~5-88¡¢ASME B16.5CL.150£¬CL.300 and ASME B16.47CL.150.

|

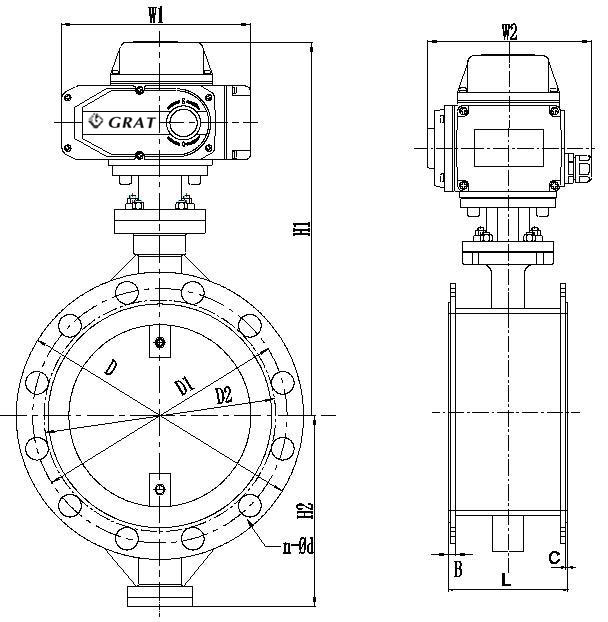

DN |

D |

D1 |

L |

B |

C |

n-Φd |

H1 |

H2 |

W1 |

W2 |

Weight |

|

50 |

140 |

110 |

108 |

14 |

3 |

4-φ14 |

200 |

70 |

196 |

145 |

7 |

|

65 |

160 |

130 |

112 |

14 |

3 |

4-φ14 |

210 |

80 |

196 |

145 |

8 |

|

80 |

190 |

150 |

114 |

14 |

3 |

4-φ18 |

220 |

95 |

196 |

145 |

9 |

|

100 |

205 |

170 |

127 |

14 |

3 |

4-φ18 |

240 |

105 |

196 |

145 |

10 |

|

125 |

235 |

200 |

140 |

14 |

3 |

8-φ18 |

260 |

120 |

196 |

145 |

12 |

|

150 |

260 |

225 |

140 |

16 |

3 |

8-φ18 |

280 |

132 |

196 |

145 |

14 |

|

200 |

315 |

280 |

152 |

18 |

3 |

8-φ18 |

320 |

160 |

196 |

145 |

29 |

|

250 |

370 |

335 |

165 |

22 |

3 |

12-φ18 |

350 |

187 |

196 |

145 |

31 |

|

300 |

435 |

395 |

178 |

22 |

4 |

12-φ22 |

370 |

220 |

196 |

145 |

34 |

|

350 |

485 |

445 |

190 |

22 |

4 |

12-φ22 |

390 |

245 |

196 |

145 |

162 |

|

400 |

535 |

495 |

216 |

22 |

4 |

16-φ22 |

420 |

270 |

196 |

145 |

168 |

|

450 |

590 |

550 |

222 |

24 |

4 |

16-φ22 |

450 |

297 |

196 |

145 |

177 |

|

500 |

640 |

600 |

229 |

24 |

4 |

20-φ22 |

460 |

322 |

196 |

145 |

190 |

|

600 |

755 |

705 |

267 |

24 |

5 |

20-φ28 |

520 |

377 |

196 |

145 |

213 |

|

700 |

860 |

810 |

292 |

28 |

5 |

24-φ26 |

600 |

430 |

255 |

184 |

276 |

|

800 |

975 |

920 |

318 |

28 |

5 |

24-φ30 |

650 |

487 |

255 |

184 |

304 |

|

900 |

1075 |

1020 |

330 |

28 |

5 |

24-φ30 |

700 |

537 |

255 |

184 |

327 |

|

1000 |

1175 |

1120 |

410 |

28 |

5 |

28-φ30 |

750 |

587 |

255 |

184 |

349 |

|

1200 |

1405 |

1340 |

470 |

28 |

5 |

32-φ33 |

860 |

702 |

255 |

184 |

394 |

|

1300 |

1475 |

1420 |

510 |

32 |

5 |

36-φ30 |

920 |

760 |

255 |

184 |

564 |

|

1400 |

1630 |

1560 |

530 |

32 |

5 |

36-φ30 |

940 |

782 |

255 |

184 |

644 |

|

1500 |

1690 |

1630 |

580 |

32 |

5 |

40-φ36 |

1080 |

860 |

255 |

184 |

695 |

|

1600 |

1830 |

1760 |

600 |

32 |

5 |

40-φ36 |

1100 |

895 |

255 |

184 |

744 |

|

1800 |

2045 |

1970 |

670 |

34 |

5 |

44-φ39 |

1160 |

995 |

255 |

184 |

875 |

|

2000 |

2265 |

2180 |

760 |

34 |

5 |

48-φ42 |

1280 |

1095 |

255 |

184 |

984 |

Properties and Specifications

|

Valve size DN |

DN50-DN2000 |

|

|

Body ratings PN |

0.1MPa |

|

|

Test pressure |

Body test |

0.15MPa |

|

Seal test |

0.11MPa |

|

|

Operating temperatuer¡æ |

£¼200¡æ Special: £¼450¡æ |

|

|

Applicable medium |

smoke,air,gas. |

|

The material of the main parts

|

Part name |

Material |

|

Body |

Q235-B, 20, 20g etc. |

|

Disc |

|

|

Rotatable shaft |

45, 40Cr etc. |

|

Packing |

YS250F etc. |

|

Handle |

KTH33008 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...