Classification£º¡¡Electric ball valve

Product Name£º¡¡Quick Switch Electric Ball Valve

Product Description£º

EK series quick switch electric ball valve is widely used in the technical piping of large pressure drops and easy blocking to quickly switch and cut off the medium of pipeline, whose superior product performance and cost-effective far exceeds the competitive products of solenoid valve.

This series can fully satisfy the requirements to quickly switch and cut off the medium to realize the control over the technical parameters of pressure, flow, temperature, and the level of liquid.

The superior technical performance makes the product widely apply in various industrial fields of industrial boiler, water supply and pipeline transmission to cut off pipeline medium.

¡ïLong service life

More than 50,000 operation life without fault, keep your system operating safely and reliably.

The newest driver technology of quick switch electric actuator makes the valves have no power consumption at idle time, and need a little of electric power only at work, which effectively reduces the operation cost of system.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïShort switch time

The valve can complete the switch action in 3~4s.

¡ïLarge allowable pressure drops

The pressure drops resistance reaches more than 1.0Mpa.

¡ïThe valve owns a self-cleaning function to effectively guarantee the piping circulating.

The valve can easily cut off all kinds of impurities in the pipeline to effectively guarantee the pipeline circulating.

¡ïGood seal performance, zero leakage

The valve with two-sided sphere seal function can reach zero leakage.With the whole baking finish surfaces, the valve can effectively prevent rusting, and is suited to different medium when better seal rings or seal materials are assembled.

¡ïWidely adaptability, various connection mode (flange type, wafer type, double plastic union etc. )

This valve presents small volume, light weight, reliable performance, simple configurement.

Body is matched with a standard convex pipe flanges.

¡ïSimple and reliable straight-through structure, free to maintain.

Compared with the S channel structure of solenoid valve, the simple channel has the advantages with small flow resistance and no block.

The valve never needs maintenance from the beginning of first operation.There is no material accumulation near the body.

¡ïSmall flow resistance, big flow capacity, suitable for complex working conditions, easy to install

The ball valve is one of the least flow resistances in all valves, even reduced diameter ball valve, whose flow resistance is quite small.

The thrust bearing reduces friction torque of the stem, and can make the stem operate evenly and flexibly for a long time.

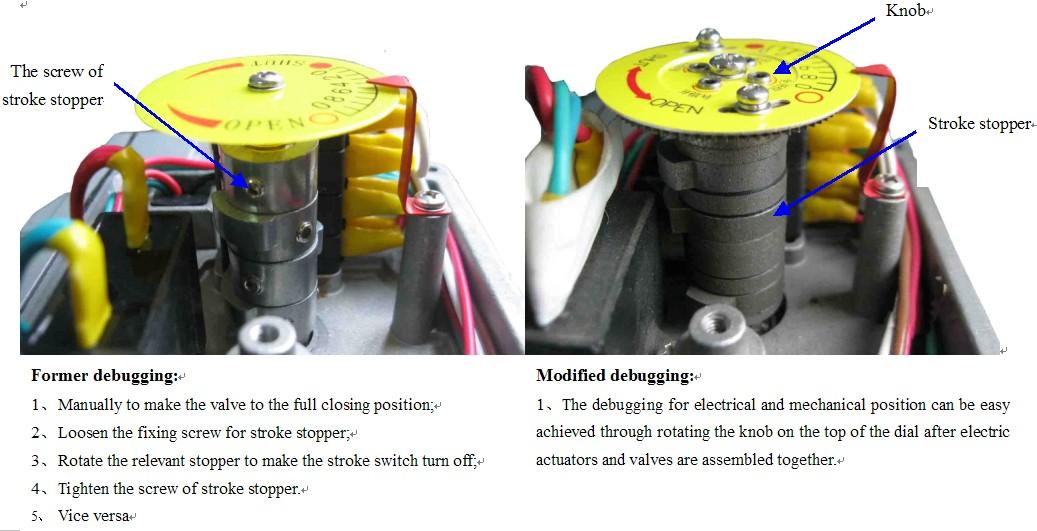

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Power supply: AC220V 50/60HZ

Body ratings: DN15-100

Medium Temp. ≤220¡æ

Ambient Temp. ≤50¡æ

Operating pressure: PN16, PN25, PN40

Action mode: Switch to cut off

Body connections: Flange type, connecting thread.

Body material: Stainless steel SUS304¡¢SUS316¡¢Carbon steel/ Casting steel WCB

Plug material: Stainless steel SUS304¡¢SUS316¡¢Carbon steel/ Casting steel WCB

Leakage: Compliance with the standards ANSIB16.104 5

Seal type: Two-sided sphere seal

Applicable medium: Water, oil, gas

Protection level: IP67

Dead zone: 0.5%

Repeatability error: 0.5%

The compliance standards of the products

Manufacturing standards: JB/T8692-1998

Design standards£ºGB12237-89 AP16D

Flange standards£ºJB79 GB9113 ANSI B16.5 JIS B2212

Structure length standards£ºGB1221-89

Inspection standards£ºJB/T 9092 API598

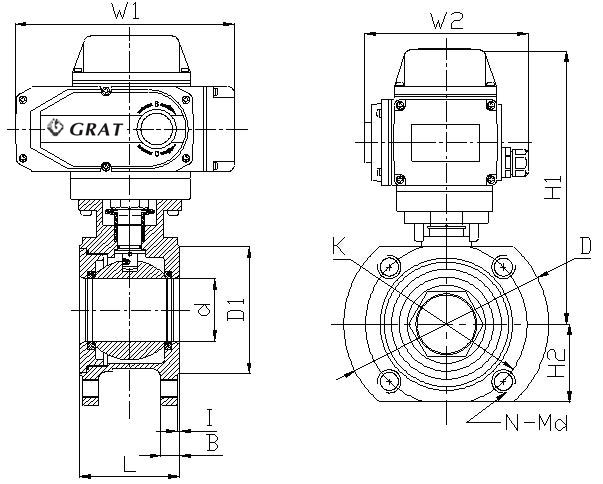

|

DN |

L |

D |

K |

D1 |

N-Md |

B |

I |

H1 |

H2 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

||||||||||||

|

15 |

1/2″ |

35 |

95 |

65 |

46 |

4-φM12 |

9 |

2 |

234 |

196 |

145 |

196 |

5.6 |

|

20 |

3/4″ |

38 |

100 |

75 |

56 |

4-φM12 |

12 |

2 |

242 |

196 |

145 |

196 |

6 |

|

25 |

1″ |

42 |

110 |

85 |

66 |

4-φM12 |

12.7 |

2 |

218 |

196 |

145 |

196 |

5.8 |

|

32 |

11/4″ |

52 |

133 |

100 |

78 |

4-φM16 |

14 |

3 |

231 |

196 |

145 |

196 |

6.7 |

|

40 |

11/2 |

61 |

145 |

110 |

87 |

4-φM16 |

15 |

3 |

238 |

196 |

145 |

196 |

7.6 |

|

50 |

2 |

73 |

160 |

125 |

99 |

4-φM16 |

16.7 |

3 |

251 |

196 |

145 |

196 |

8.7 |

|

65 |

21/2″ |

92 |

180 |

145 |

118 |

4-φM16 |

17.2 |

3 |

265 |

196 |

145 |

196 |

16.8 |

|

80 |

3″ |

109 |

195 |

160 |

136 |

8-φM16 |

19 |

3 |

298 |

255 |

184 |

255 |

18.6 |

|

100 |

4″ |

140 |

215 |

180 |

156 |

8-φM16 |

18.5 |

3 |

310 |

255 |

184 |

255 |

21.2 |

|

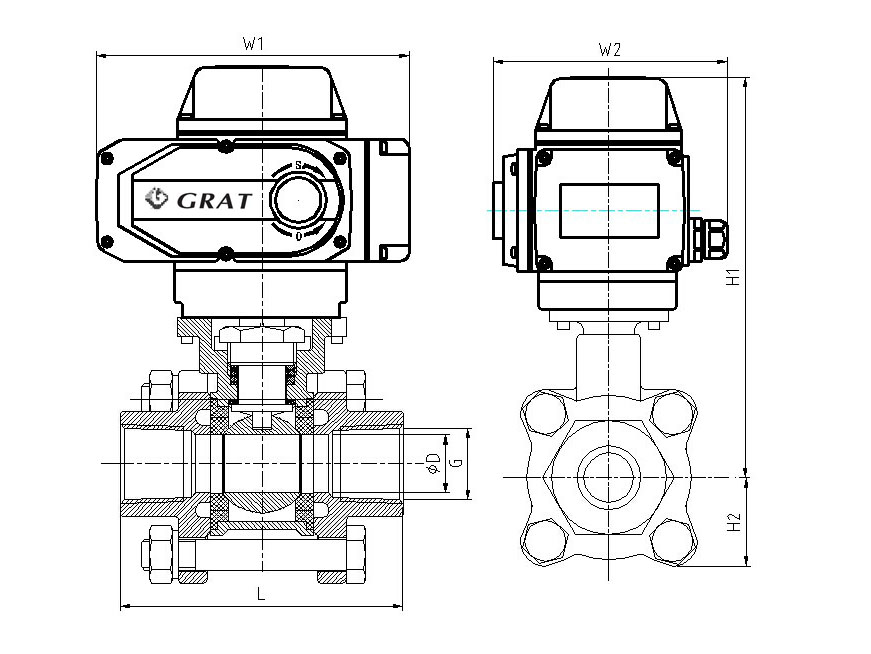

DN |

D |

G |

L |

H1 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

|||||||

|

8 |

1/2″ |

8 |

14.3 |

65 |

177 |

196 |

145 |

5.0 |

|

10 |

3/4″ |

10 |

18 |

65 |

177 |

196 |

145 |

5.2 |

|

15 |

1″ |

15 |

22 |

72 |

188 |

196 |

145 |

5.3 |

|

20 |

11/4″ |

18 |

28 |

85 |

190 |

196 |

145 |

5.5 |

|

25 |

11/2 |

24 |

34.5 |

91 |

200 |

196 |

145 |

5.3 |

|

32 |

2 |

30 |

43.5 |

110 |

205 |

196 |

145 |

5.9 |

|

40 |

1/2″ |

38 |

49.5 |

122 |

212 |

196 |

145 |

6.2 |

|

50 |

3/4″ |

48 |

62 |

145 |

220 |

196 |

145 |

7.2 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...