Classification£º¡¡Electric ball valve

Product Name£º¡¡Stainless Steel Flange Electric Ball Valve

Product Description£º

EK series stainless steel flange electric ball valve is a rotating ball valve with the angle range from 0 degree to 90 degree, which presents good seal performance, large flow capacity, small flow resistance coefficient, simple structure, convenient maintenance, long service life. The channel of the body and the connecting pipe has the equal diameter to be connected together, which allows medium to flow almost no loss. The EK series valves are usually used in the occasion of high sealing performance requirements to control not only the medium of gas, liquid, but also the medium of sewage and fibrous impurity medium, which is widely applied in the fields of petroleum, chemical, metallurgy, light industry, papermaking, power station, refrigeration and so on.

The working principle of electric ball valves: electric actuators drive the stem to rotate together with the ball with a hole (or part of the ball) to realize the valve switch. The valve can open and close fully by rotating 0-90 °. Compared with the same specifications of the gate valve and globe valve, the ball valve is smaller, lighter and easier installation in pipeline.

¡ïGood seal performance, long service life

More than 50,000 operation life without fault, keep your system operating safely and reliably.

The seat with PTFE seal ring has good seal performance, whose structure is easy to seal, and the seal capacity of ball valve increases with the increase of the medium pressure.

The seal performance of stem is reliable, because the stem only rotates without doing the lifting movement so that stem filling materials is not easy to be destroyed, and the seal capacity of ball valve increases with the increase of the medium pressure.

With good self-lubrication properties, PTFE materials make small friction loss with body to prolong the service life of ball valve.

The convex step at head of bottom-up installed stem prevents stem from being ejected. When the fire accident broke the sealing of stem, a metal contact is formed between the convex step and stem to assure seal performance of stem.

¡ïSmall flow resistance, big flow capacity, suitable for complex working conditions, easy to install.

The ball valve is one of the least flow resistances in all valves, even reduced diameter ball valve, whose flow resistance is quite small.

The thrust bearing reduces friction torque of the stem, and can make the stem operate evenly and flexibly for a long time.

This series of valves adopt the integrated structure, whose rotation can be controlled by single phase power, and which are stronger, smaller, lighter, portable, simple configuration, large flow capability.

The valve is very suitable for the occasion of high seal performance and big pipeline pressure drops to switch and cut off the medium of pipeline.

¡ïSimple structure, easy to operate, high cost-effective.

The regulation type electric actuator and the stem have been connected and debugged well, then the stem is driven by electric energy to realize the ball body gyrating partly from 0~90°.

The valve is accurately controlled via switch signal 4~20mA from industrial automation control system, which regulates and controls the different technical parameters of the flow, temperature, and pressure.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïBeautiful appearance, compact structure, various choice of sealed type

This valve is an innovative optimized design by three-dimensional model of CAD, which has a beautiful and compact appearance and modern modeling.

The series valves adopt new material and new technology including 4 sealed forms respectively elastic sealing, high temperature resistant digital polystyrene, hard alloy and industrial ceramics, which ensures that the product presents many advantages such as the good quality, good product performance, more reliable, more economical, more durable.

The products are fully compliance with the latest technical specifications of international standard, which is the first choice for future automation system.

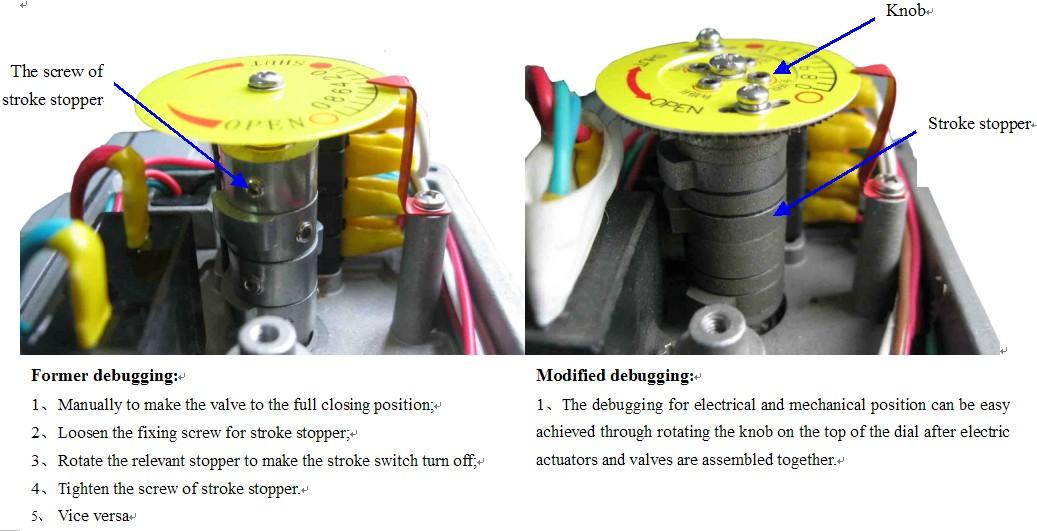

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Power supply: AC220V 50/60HZ

Valve size: DN15-200

Medium Temp. -20¡æ ~ +350¡æ (+200¡æ special seal).

Operating pressure: PN16, PN25 - PN40 - PN64 -PN100

Input signal: 4-20mA

Output signal: 4-20mA

Body connections: Wafer

Body material: A105¡¢F304¡¢F316¡¢WCB¡¢FZG1Cr18Ni9Ti¡¢ZG1Cr18Ni12Mo2Ti¡¢CF8¡¢CF8M¡¢CF3M

Seat material: PTFE(room temperature)¡¢Specialty PPL£¨high temperature£©¡¢Metal seal£¨high temperature£©

Leakage: Compliance with the standards of ANSIB16.104 5 grade

Sealed type: Elastic sealing, high temperature resistant digital polystyrene, hard alloy and industrial ceramics

Applicable medium: Water, oil, nitric acid, acetic acid, viscous liquid, slurry, strong oxidizing medium etc.

Protection levels£ºIP67

The compliance standards of the products

Manufacturing standards£ºJB/T8692-1998

Design standards: GB12237-89 AP16D

Flange standards: JB79 GB9113 ANSI B16.5 JIS B2212

Structure length standards: GB1221-89

Inspection standards: JB/T 9092 API598

|

DN(mm) 1.6Mpa |

L |

D |

K |

D1 |

n-Φd |

b |

f |

H1 |

H2 |

W1 |

W2 |

Weight |

|

15 |

130 |

95 |

65 |

46 |

4-Φ14 |

14 |

2 |

250 |

50 |

196 |

145 |

¡¡ |

|

20 |

140 |

105 |

75 |

56 |

4-Φ14 |

16 |

2 |

255 |

55 |

196 |

145 |

¡¡ |

|

25 |

150 |

115 |

85 |

65 |

4-Φ14 |

16 |

2 |

260 |

60 |

196 |

145 |

¡¡ |

|

32 |

165 |

135 |

100 |

76 |

4-Φ18 |

18 |

3 |

270 |

70 |

196 |

145 |

¡¡ |

|

40 |

180 |

145 |

110 |

84 |

4-Φ18 |

18 |

3 |

275 |

75 |

196 |

145 |

¡¡ |

|

50 |

200 |

160 |

125 |

99 |

4-Φ18 |

20 |

3 |

285 |

85 |

196 |

145 |

¡¡ |

|

65 |

220 |

180 |

145 |

118 |

4-Φ18 |

20 |

3 |

350 |

95 |

255 |

184 |

¡¡ |

|

80 |

250 |

195 |

160 |

132 |

8-Φ18 |

20 |

3 |

360 |

100 |

255 |

184 |

¡¡ |

|

100 |

280 |

215 |

180 |

156 |

8-Φ18 |

22 |

3 |

370 |

110 |

255 |

184 |

¡¡ |

|

125 |

320 |

245 |

210 |

184 |

8-Φ18 |

22 |

3 |

380 |

125 |

255 |

184 |

¡¡ |

|

150 |

360 |

280 |

240 |

211 |

8-Φ22 |

24 |

3 |

390 |

140 |

255 |

184 |

¡¡ |

|

200 |

400 |

335 |

295 |

266 |

12-Φ22 |

24 |

3 |

420 |

170 |

255 |

184 |

¡¡ |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...