Classification£º¡¡Electric control valve

Product Name£º¡¡GRAT Electric Proportional Control Valve

Product Description£º

As an automatic control equipment to regulate the technical parameters of flow, temperature, pressure, GRAT electric proportional control valve is suitable for various industrial automation computer control system, DCS system, and gauges, whose Main applications are industrial automation production process control fields. For example: Petrochemical refinery, crude oil pipeline, cooling steam turbine for power plant, lubricant oil supply, combustion air volume adjustment; environmental protection sewage treatment in the liquid conveying cut-off, switches, flow control and other industrial automation process control.

¡ïThe characteristics of flow control

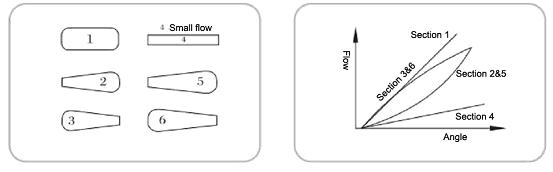

Unique V type structure for the plug solved the control stability problem of traditional ball valve. For the stability of flow regulation, the EQ% characteristics can make the open degree between the controlled object and the valve tend to linearity. When the valve opens, the flow increases very slowly. The plug type determines the valve properties, so different open type of plug , and so the same diameter of the valve has different CV values and flow characteristics.

¡ïLong service life

More than 50,000 operation life without fault, keep your system operating safely and reliably.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïMiniature design

Light weight: The overall structure of valve body makes the ultra short face-to-face dimension, and greatly reduced the overall weight, which is about 50% weight of the same type ball valve.

Small volume: The valve is easy to install in any direction of the pipeline, which is suitable for various complex pipeline and working conditions.

¡ïGood seal performance

The valve owns the double sphere sealing to enhance sealing strength and effectively control the leakage to zero leakage. The sealing level is grade VI.

¡ïThe valve owns a self-cleaning function to effectively guarantee the piping circulating.

The scissors opening between the valve seat and the trim can easily cut off all kinds of impurities in the pipeline to effectively guarantee the pipeline circulating.

¡ïHigh modulation precision

The valve has high modulation precision, large rangeability (Maximum 300:1), and excellent modulation performance to make it widely applied in various industrial fields for high precision adjustment.

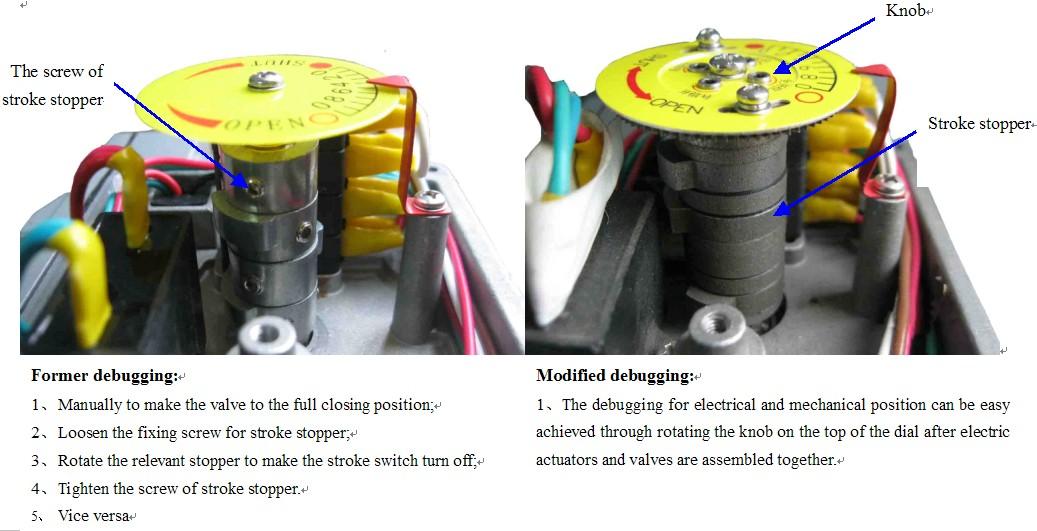

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Valve size: DN15-DN200£¨Please contact us for the larger diameter information.£©

Body ratings: PN1.6MPa

Body connections: Flange

Seat form: PTFE Soft seal

Body material: SUS304 SUS316 WCB

Stem material: SUS304 SUS316 WCB

Action time: 15S, 30S£¨optional£©£¨0-90°£©

Power supply: AC220V, AC380V, DC24V

Control signal: 4¡«20mA, 0¡«5V

Output signal: 4¡«20mA 0,¡«5V

Operating pressure: PN1.6Mpa, PN2.5Mpa, PN6.4Mpa

Medium Temp. ≤220¡æ

Ambient Temp. ≤50¡æ

Flow coefficient£¨CV£©: Please download the data on our website for reference¡£(Custom flow coefficient depends on the customer’s requirement.) Applicable medium: Food, lubrication, fibrous fluid, water, oil, gas.

Dead zone: 0.5%

Repeatability error: 0.5%

|

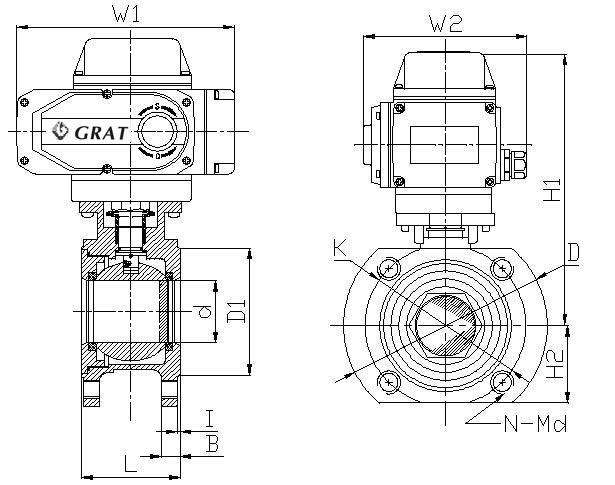

DN |

L |

D |

K |

D1 |

N-Md |

B |

I |

H1 |

H2 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

||||||||||||

|

15 |

1/2″ |

35 |

95 |

65 |

46 |

4-φM12 |

9 |

2 |

234 |

196 |

145 |

196 |

5.6 |

|

20 |

3/4″ |

38 |

100 |

75 |

56 |

4-φM12 |

12 |

2 |

242 |

196 |

145 |

196 |

6 |

|

25 |

1″ |

42 |

110 |

85 |

66 |

4-φM12 |

12.7 |

2 |

218 |

196 |

145 |

196 |

5.8 |

|

32 |

11/4″ |

52 |

133 |

100 |

78 |

4-φM16 |

14 |

3 |

231 |

196 |

145 |

196 |

6.7 |

|

40 |

11/2 |

61 |

145 |

110 |

87 |

4-φM16 |

15 |

3 |

238 |

196 |

145 |

196 |

7.6 |

|

50 |

2 |

73 |

160 |

125 |

99 |

4-φM16 |

16.7 |

3 |

251 |

196 |

145 |

196 |

8.7 |

|

65 |

21/2″ |

92 |

180 |

145 |

118 |

4-φM16 |

17.2 |

3 |

265 |

196 |

145 |

196 |

16.8 |

|

80 |

3″ |

109 |

195 |

160 |

136 |

8-φM16 |

19 |

3 |

298 |

255 |

184 |

255 |

18.6 |

|

100 |

4″ |

140 |

215 |

180 |

156 |

8-φM16 |

18.5 |

3 |

310 |

255 |

184 |

255 |

21.2 |

|

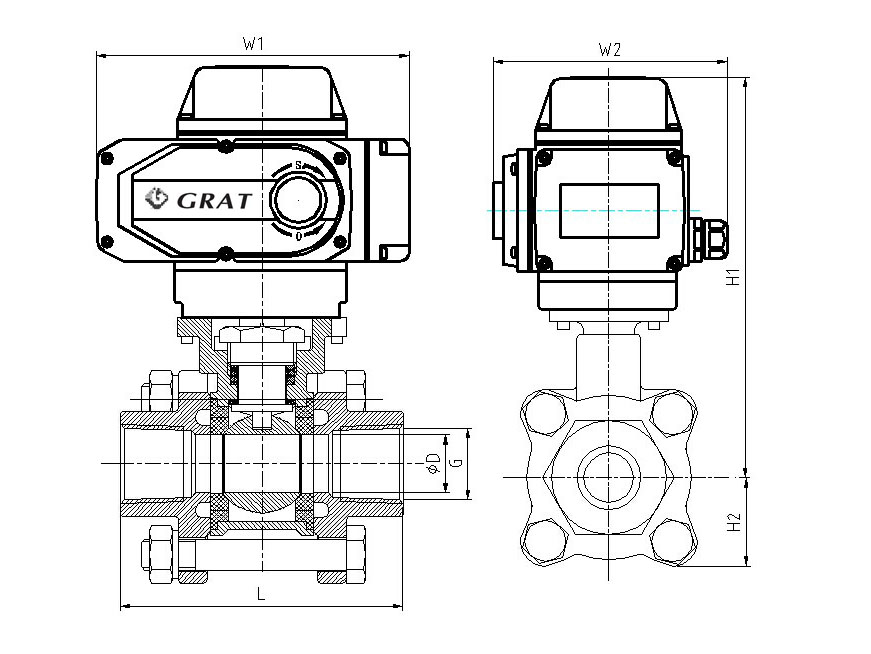

DN |

D |

G |

L |

H1 |

W1 |

W2 |

Weight Kg |

|

|

mm |

inch |

|||||||

|

8 |

1/2″ |

8 |

14.3 |

65 |

177 |

196 |

145 |

5.0 |

|

10 |

3/4″ |

10 |

18 |

65 |

177 |

196 |

145 |

5.2 |

|

15 |

1″ |

15 |

22 |

72 |

188 |

196 |

145 |

5.3 |

|

20 |

11/4″ |

18 |

28 |

85 |

190 |

196 |

145 |

5.5 |

|

25 |

11/2 |

24 |

34.5 |

91 |

200 |

196 |

145 |

5.3 |

|

32 |

2 |

30 |

43.5 |

110 |

205 |

196 |

145 |

5.9 |

|

40 |

1/2″ |

38 |

49.5 |

122 |

212 |

196 |

145 |

6.2 |

|

50 |

3/4″ |

48 |

62 |

145 |

220 |

196 |

145 |

7.2 |

|

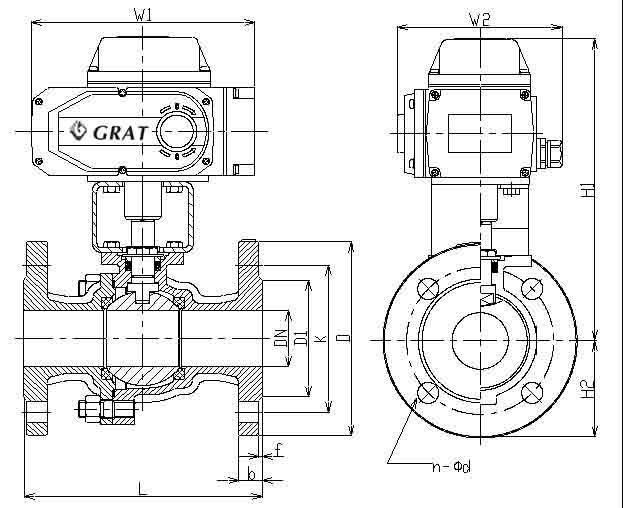

DN(mm) 1.6Mpa |

L |

D |

K |

D1 |

n-Φd |

b |

f |

H1 |

H2 |

W1 |

W2 |

Weight |

|

15 |

130 |

95 |

65 |

46 |

4-Φ14 |

14 |

2 |

250 |

50 |

196 |

145 |

¡¡ |

|

20 |

140 |

105 |

75 |

56 |

4-Φ14 |

16 |

2 |

255 |

55 |

196 |

145 |

¡¡ |

|

25 |

150 |

115 |

85 |

65 |

4-Φ14 |

16 |

2 |

260 |

60 |

196 |

145 |

¡¡ |

|

32 |

165 |

135 |

100 |

76 |

4-Φ18 |

18 |

3 |

270 |

70 |

196 |

145 |

¡¡ |

|

40 |

180 |

145 |

110 |

84 |

4-Φ18 |

18 |

3 |

275 |

75 |

196 |

145 |

¡¡ |

|

50 |

200 |

160 |

125 |

99 |

4-Φ18 |

20 |

3 |

285 |

85 |

196 |

145 |

¡¡ |

|

65 |

220 |

180 |

145 |

118 |

4-Φ18 |

20 |

3 |

350 |

95 |

255 |

184 |

¡¡ |

|

80 |

250 |

195 |

160 |

132 |

8-Φ18 |

20 |

3 |

360 |

100 |

255 |

184 |

¡¡ |

|

100 |

280 |

215 |

180 |

156 |

8-Φ18 |

22 |

3 |

370 |

110 |

255 |

184 |

¡¡ |

|

125 |

320 |

245 |

210 |

184 |

8-Φ18 |

22 |

3 |

380 |

125 |

255 |

184 |

¡¡ |

|

150 |

360 |

280 |

240 |

211 |

8-Φ22 |

24 |

3 |

390 |

140 |

255 |

184 |

¡¡ |

|

200 |

400 |

335 |

295 |

266 |

12-Φ22 |

24 |

3 |

420 |

170 |

255 |

184 |

¡¡ |

The flow figure of several typical section shape and flow characteristics

The main technical parameters and indexes of body

|

Valve size DN(mm) |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

|

|

CV flow coefficient at a fully open £¨for reference£© |

“O” shape |

24 |

44 |

84 |

122 |

198 |

320 |

443 |

595 |

1096 |

1692 |

2602 |

4212 |

|

Rectangle |

8.7 |

13.4 |

20 |

32.6 |

44.3 |

70 |

114 |

134 |

186 |

270 |

462 |

688 |

|

|

“V” shape 30° |

7.5 |

11 |

17 |

28 |

38 |

60 |

98 |

116 |

155 |

233 |

397 |

595 |

|

|

Flow characteristics |

J rectangle: linearity, “V” shape£¨logarithm£©EQ%, “O” shape: Quick open |

||||||||||||

|

Body rating MPa |

16£¨1.6MPa£©¡¢40£¨4.0MPa£©¡¢64£¨6.4MPa£© |

||||||||||||

|

Adjustable rate |

50:1 100:1 300:1 |

||||||||||||

|

Flange standard |

Compliance with the standard JB78-59¡¢JB-79-59£»manufacture according to the standard JB/T79.1¡¢JB/T79.2-94 |

||||||||||||

|

Body material |

Casting steel£¨ZG230-450£©¡¢Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L£©¡¢titanium alloy |

||||||||||||

|

Ball material |

Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L¡¢A105£©etc. |

||||||||||||

|

Stem material |

Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L£© |

||||||||||||

|

Packing material |

PTFE, Grafoil |

||||||||||||

|

Seal type |

Soft seat |

Metal seat |

|||||||||||

|

Seat material |

PTFE |

Carbon fiber intensified PTFE |

Stainless steel or stainless steel+ STL |

||||||||||

|

Leakage |

¢ö degree |

less than rated flow10-4¡¢10-5 |

|||||||||||

|

Operating Temp. |

N: -40¡æ-180¡æ |

M: -40¡æ-280¡æ |

H: -40¡æ-400¡æ |

||||||||||

The implementation standards of the electric control valve

|

Manufacturing standards |

GB/T 122387-89 |

|

Flange standards |

GB9113-2000, GB17241.6-1998 |

|

Structure length standards |

GB12221-89 |

|

Inspection standards |

GB/T 13927-92 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...