Classification£º¡¡Electric control valve

Product Name£º¡¡Single Seat Control Valve

Product Description£º

With a spherical body, the EP series single seat control valve presents a top guided structure, which has compact structure, high modulation accuracy, small pressure drop loss, accurate flow characteristics, big oriented area, anti-vibration etc.

The EP series single seat control valves have the large output torque, flexible action, large rangeability, convenient maintenance, which is suited to various severe services to control the various liquid.

The EP series valves are widely applied in petroleum, chemical, electric power, textile, papermaking, which is especially suitable for small leakage application and small pressure drops application in front and rear of the valve.

¡ïLow price, a broad scope of application

The valve with high performance and metal seal adopts partial stellite seal ring to realize high temperature resistance for 350 ¡æ.

The unique body structure with long stem can effectively increase the distance between the actuator and high temperature medium, which has a better heat dissipation performance.

¡ïLarge thrust, specially suitable for large diameter pipeline

Unique integrated structure for the stem and plug can effectively solve the problem of mechanical gyration error.

The gyration error is less than 0.5%.

¡ïLarge rangeability, the flow curve is approximate to EQ%

With large rangeability, the valve has an inherent rangeability 50, whose flow characteristic includes linearity and equal percentage.

¡ïThe valve owns a self-cleaning function, which can effectively guarantee the piping circulating.

The valve can easily cut off all kinds of impurities in the pipeline to guarantee the pipeline circulating.

¡ïDesign for high temperature resistance, allowing a large pressure drops

The equal pressure holes are set above and below the plug to make the electric cage control valves present small unbalanced force, good stability, large pressure drops and strong interchangeability for cage.

Valve size: DN20-DN200

Body ratings: PN1.6MPa

Body connections: Flange, thread, weld

Seat form: Single seat

Plug form: Plunger type

Power supply: AC220V

Structure type: Standard type, modulation & cutting off type, thermal dissipation type, low temperature type, bellows type, heat insulation jacket type

Operating pressure: PN1.6Mpa PN2.5Mpa PN4.0Mpa PN6.4Mpa

Medium Temp. ≤550¡æ

Ambient Temp. ≤50¡æ

Flow coefficient £¨CV£©: Please download the data on our website for reference¡£(Custom flow coefficient depends on the customer’s requirement.)

Body material: SUS304 SUS316 WCB

|

Valve size DN£¨mm£© |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

||||||

|

L |

PN16. 40 |

150 |

160 |

180 |

200 |

230 |

290 |

310 |

350 |

400 |

480 |

600 |

|||||

|

PN64. 100 |

206 |

210 |

230 |

251 |

286 |

311 |

337 |

394 |

450 |

508 |

650 |

||||||

|

H |

PN16. 40 |

52 |

57 |

75 |

75 |

82 |

92 |

100 |

117 |

150 |

167 |

187 |

|||||

|

PN64. 100 |

65 |

40 |

85 |

85 |

90 |

103 |

108 |

125 |

173 |

195 |

208 |

||||||

|

H1 |

125 |

125 |

155 |

155 |

165 |

200 |

205 |

210 |

275 |

330 |

372 |

||||||

|

A*H2 |

§æ225*370 |

§æ255*500 |

§æ310*700 |

§æ310*750 |

|||||||||||||

|

Weight(kg) |

PN16 |

20 |

21 |

24 |

33 |

37 |

65 |

68 |

56 |

118 |

145 |

215 |

|||||

|

PN64 |

23 |

24 |

32 |

44 |

53 |

76 |

81 |

100 |

156 |

178 |

265 |

||||||

Actuator prarmeters

| Valve size DN£¨mm£© |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Electric actuator thrust£¨N£© | Common type | 400~4000 | 400~4000 | 6400 | 6400~16000 | |||||||

| Electronic type | 2000 | 4000 | 6000 | 8000 | ||||||||

| Full stroke time £¨S£© |

Common type | 12.5 | 20 | 32 | 48 | |||||||

| Electronic type | 30 | 30 | 48 | 60 | ||||||||

| Consumptive power £¨W£© |

Common type | 28 | 35 | |||||||||

| Electronic type | 6 | 15 | 25 | 40 | ||||||||

Specification and technical parameters

| Valve size DN(mm) |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Rated flow coefficient KV | Linearity | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 |

| EQ% | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | |

| Rated stroke L£¨mm£© | 16 | 25 | 40 | 60 | ||||||||

| Body rating Mpa | 16£¨1.6MPa£©¡¢40£¨4.0MPa£©¡¢64£¨6.4MPa£© | |||||||||||

| Inhere rangability | 50 | |||||||||||

| Flange standards | Compliance with standard JB78-59¡¢JB-79-59, manufacture according to the standard JB/T79.1¡¢JB/T79.2-94 | |||||||||||

| Body material | Cast steel£¨ZG230-450£©¡¢Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L£©¡¢Titanium alloy | |||||||||||

| Ball material | Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L¡¢A105£©etc. | |||||||||||

| Stem material | Stainless steel£¨ZG1Cr18Ni9Ti¡¢316¡¢316L£© | |||||||||||

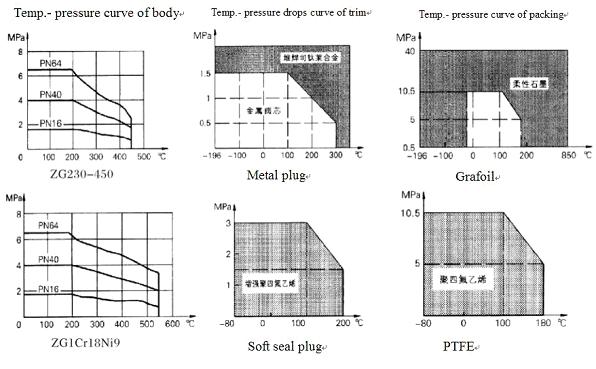

| Packing material | PTFE, Grafoil | |||||||||||

| Seal Type | Metal seat | Soft seat | ||||||||||

| Seat material | PTFE | Carbon fiber intensified PTFE | Stainless steel or stainless steel +STL | |||||||||

| Leakage | ¢ö grade | less than rated flow10-4¡¢10-5 | ||||||||||

| Operating Temp. | N:-40¡æ-180¡æ | M:-40¡æ-280¡æ | H:-40¡æ-400¡æ | |||||||||

The operating temperature and pressure range of trim and packing materials

![]()

The implementation standards of the electric control valve

|

Manufacturing standards |

GB/T 122387-89 |

|

Flange standards |

GB9113-2000¡¢GB17241.6-1998 |

|

Structure length standards |

GB12221-89 |

|

Inspection standards |

GB/T 13927-92 |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...