Classification: Electric ball valve

Product Name: UPVC Electric Ball Valve

Product Description:

UPVC Electric Ball Valve is widely applied in the industrial fields of acid, alkali and chemical solution.

The body with light weight and strong corrosion resistance is widely used in the piping system of pure water and raw drinking water, drainage and sewage, salt water and sea water.

★Beautiful appearance, compact structure

This valve with an innovative optimized design by three-dimensional model of CAD has a beautiful and compact appearance and modern modeling, and adopts new material and new technology to ensure that the valve has the good quality, good product performance, more reliable, more economical, more durable, which is fully compliance with the latest technical specifications of international standard, and which is the first choice for future automation system.

★Strong corrosion resistance, a broad scope of application.

The valve owns excellent corrosion resistance to chemical.

The UPVC electric ball valve with strong corrosion resistance is widely applied in various piping systems of pure water, raw drinking water, drainage, sewage, salt water, sea water, acid solution, alkali solution, chemical solution, whose quality has been recognized by numbers of users.

★Light weight, diversified performance, easy installation

The lightweight body is equivalent to 1/5 weight of steel pipe and 1/6 weight of copper pipe.

The actuator has enough torque, lightweight, small volume and convenient installation.

The valve owns excellent strength and toughness, abrasion resistance, easy to disassemble, simple and easy maintenance.

The flame-retardant performance is realized by its self-extinguishing.

Compared with other pipeline systems, the excellent aging resistance and UV resistance ensures that the product’s normal service life is extended a lot than that of other pipeline system.

The low thermal-conductivity performance equates about 1/200 of steel.

The used material is health and non-toxic, which complies with national health standards.

The clean and smooth pipe wall can transmit liquid with small friction resistance and adhesive force.

★The patent localization technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

★Simple structure, easy to operate, high cost-effective.

This UPVC electric ball valve is applied in the occasion of regulating and cutting off by two position. It’s direct connection between the valve and actuator.

The electric actuators with servo system inside never need be configured with the servo amplifier, whose operation can be controlled by inputting 4-20mA signal and 220VAC power. The valve presents simple connection, compact structure, small resistance, stable and reliable action.

The valve is controlled accurately via switch signal 4~20mA from industrial automation control system, which regulate and control the different technical parameters of the flow, temperature, pressure.

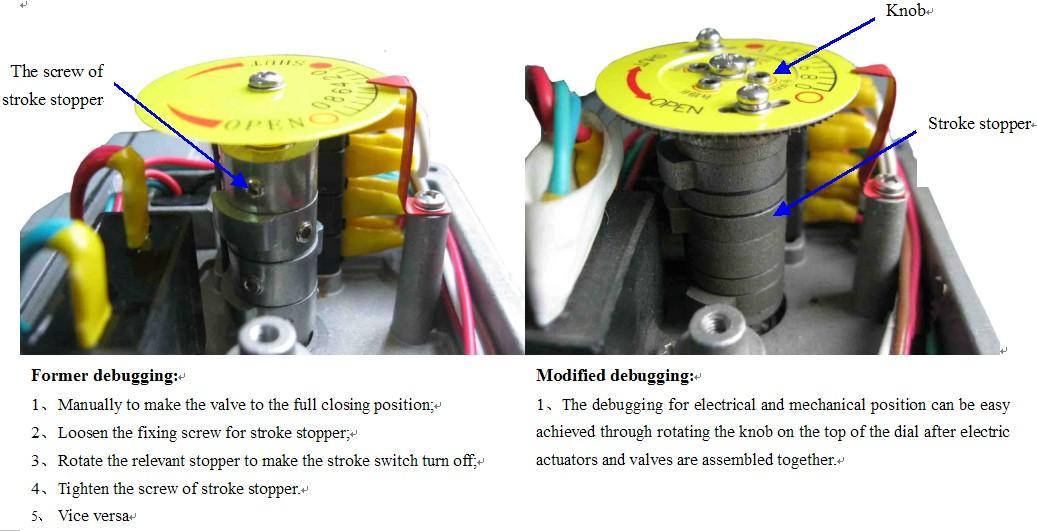

★The new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Power supply: AC220V 、AC24V

Valve size: DN10-100

Medium Temp. -15℃~ 60℃(no congelation)

Ambient Temp. -25℃~ 55℃

Operating pressure: PN16,

Action mode: Switch to cut off,0 ~ 90°gyration

Action time: 4 ~ 30S

Protector: Overheat protection

Power consumption: 8VA ~ 30VA

Body connections: Flange, inside thread

Body material: UPVC

Seal material: PTFE、EPDM

Actuator material: Casting aluminum alloy, plastic shell

Applicable medium: Water, air, oil, and corrosive chemical liquid.

Protection level: IP68

Installation mode: Install it in any angle. (Prefer to horizontal or inclined installation to extend the service life.)

The compliance standards of the products

Design and manufacturing standards: GB12237-89 AP16D

Flange standards: JB79 GB9113 ANSI B16.5 JIS B2212

Structure length standards: GB1221-89

Inspection standards: JB/T 9092 API598

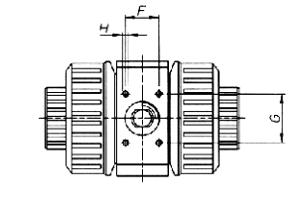

Figure and connection size

|

Size |

||||||||||||

Thread

(G) |

A |

A Adhesive interface |

B |

C Thread connection |

C Adhesive interface

|

D |

E |

F |

G |

H |

L |

φM |

|

3/8″ |

103 |

103 |

8.3 |

3/8″ |

16 |

36 |

31.5 |

24 |

24 |

M4 |

63 |

10 |

|

1/2″ |

110 |

103 |

8.3 |

1/2″ |

20 |

36 |

31.5 |

24 |

24 |

M4 |

63 |

15 |

|

3/4″ |

116 |

115 |

11 |

3/4″ |

25 |

43.5 |

36.5 |

25 |

31 |

M4 |

73 |

20 |

|

1″ |

133 |

128 |

12.1 |

1″ |

32 |

51 |

45 |

27 |

40 |

M5 |

90 |

25 |

|

1″1/4 |

145 |

146 |

14.5 |

1″1/4 |

40 |

59 |

52 |

32 |

41 |

M5 |

104 |

32 |

|

1″1/2 |

165 |

164 |

15.5 |

1″1/2 |

50 |

68 |

56 |

28 |

53 |

M6 |

112 |

40 |

|

2″ |

199 |

199 |

19 |

2″ |

63 |

82 |

67.5 |

34 |

58 |

M6 |

135 |

50 |

|

2″1/2 |

236 |

235 |

23.2 |

2″1/2 |

75 |

115 |

79 |

45 |

84 |

M6 |

105 |

65 |

|

3″ |

270 |

270 |

28.3 |

3″ |

90 |

138.5 |

100 |

55 |

102 |

M8 |

126 |

80 |

|

4″ |

309 |

308 |

28.6 |

4″ |

110 |

162.5 |

115 |

50 |

122 |

M8 |

147 |

100 |

|

Material |

|||

|

1. Shaft |

PVC |

7. Ball seal ring |

PTFE |

|

2. O-Ring |

EPDM |

8. Ball core |

PVC |

|

3. Ring nut |

PVC |

9. O-Ring |

EPDM |

|

4. Body |

PVC |

10. Plug seal bracket |

PVC |

|

5. The end |

PVC |

11. Ring |

PVC |

|

6. O-Ring |

EPDM |

|

|

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...