Classification£º¡¡Electric butterfly valve

Product Name£º¡¡Metal Seat Electric Control Butterfly Valve

Product Description£º

Metal seat electric butterfly valves have the structure of 3D eccentric metal sealed, whose seal mode is metal-to-metal, also can be changed into the other seal modes such as the metal seal ring to the metal, and the stainless steel plate seal ring or the graphite composite plate seal ring to the metal.

This 3D eccentric metal seal butterfly valve with high performance is a device to regulate and cut off the medium of those piping in petroleum, chemical, power, metallurgy and city heat supply system.

¡ïHigh temperature resistance, good seal performance, zero leakage.

EHB series metal seat electric butterfly valves have the structure of 3D eccentric metal seat, whose seal mode is metal-to-metal, also can be changed into the other seal modes such as the metal seal ring to the metal, and the stainless steel plate seal ring or the graphite composite plate seal ring to the metal.

In the situation of the high temperature and high pressure, this series valves still hold stable seal performance, and the special seal system guarantees the higher seal performance under temperature range from ultra low temperature to ultra high temperature.

3D eccentric seal system and ergonomic design make the valves have a small opening resistance. The seal surface of the disc presents a convex cone shape. When the valve is opening, the every contact around the disc departs from the seal ring at the same time, and the solids are hardly accumulated on the seal surface. The process of shutting off the valve is realized by the compression control of elastic seal ring.

There is no jam between the disc and the seal ring, and the seal performance is not affected by temperature changes.The sealing of the stem axis is realized by graphite-compacted seal ring, which assures zero leakage during the whole fire accident process. Hence, this kind of valve is called the nature valve of fire safety.

The valve adopts the advanced structure of 3D eccentric metal composite cone canting, and can reach up to zero leakage.The series valves with rubber seal hold the excellent seal performance between the disc and seat when it shut off, good two-way seal performance, small torque, and the series valves ensure zero leakage under the operating pressure.

There is almost no friction between the disc and seat due to its 3D eccentric structure, moreover, the series have the closer seal performance, the further being shut off.

¡ïSmall opening torque, no frictional rotation, long service life

The valve is operated by the working principle that the shaft drive the disc to rotate 90 degrees to realize flexible switch without jam, jumpiness, and the torque is small.More than 50,000 operation life without fault, keep your system operating safely and reliably.

The seal parts materials are mate of stainless steel and nitrile oil-proof rubber that have long service life.

¡ïSmall volume, light weight, quick switch

The valve consists of body, disc, shaft, seat and gears, which has simple and compact structure, light weight, convenience in transportation, installation, and disassembly.Switch with 90 °has the advantages of quick switch, small torque, saving energy.

The valve has excellent modulation performance, and whose flow characteristic is approximate to linearity.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïReplacing the body material, the different seal ring is suitable for different medium.

With the whole baking finish surfaces, the valve can effectively prevent rusting, and is suited to different medium by changing better seal rings or seal materials.

The body has high cost-effective, especially large diameter butterfly valve (prefer to butterfly valve in the occasions of middle and low pressure), and is configured with a convex pipe flanges.

Superior cost-effective performance makes the butterfly valves have a broad scope of application.

¡ïSimple structure, easy to operate, high cost-effective.

The modulation type electric actuator and the stem have been connected and debugged well, then the metal sealed disc is driven by electric energy to realize gyration partly from 0~90°.

The valve is accurately controlled via switch signal 4~20mA from industrial automation control system, so as to regulate and control the different technical parameters of the flow, temperature, pressure.

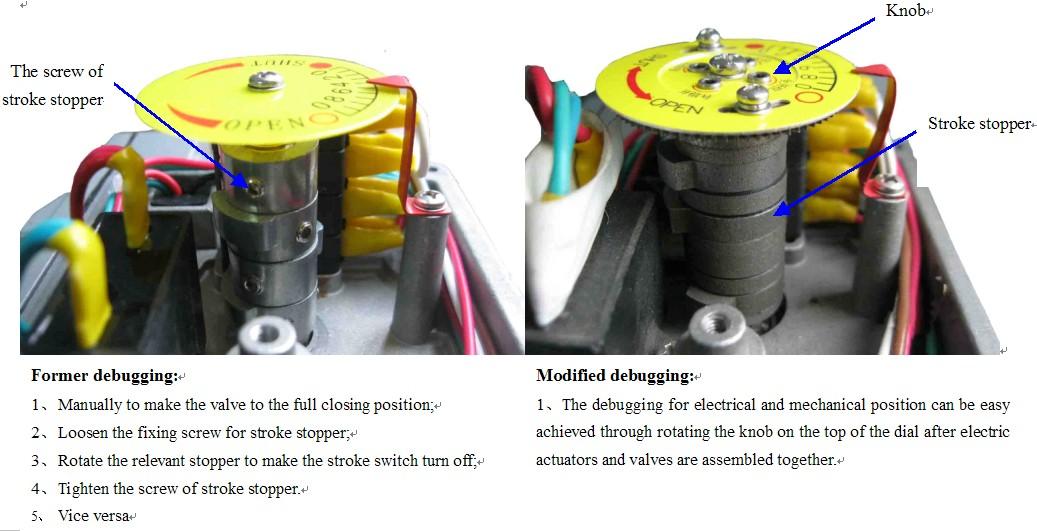

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Body ratings: PN1.0/PN1.6Mpa/PN2.5Mpa

Valve size: DN50-DN1200

Seal material: Alloy metal sealStem seal: NBR, HNBR, PTFE, GRAPHITE.

Body material: WCB/SUS304/SUS316L/CF8/CF8L Stainless Steel

Disc material: WCB/SUS304/SUS316L/CF8/CF8L Stainless Steel

Body connections: Wafer/flange

Power supply: AC220V

Control signal: 4¡«20mA 0¡«5V

Output signal: 4¡«20mA 0¡«5V

Operating pressure: PN1.6Mpa, PN2.5Mpa

Medium temperature: ≤540¡æ

The compliance standards of the products

Design and manufacturing£ºGB/T122381989, API609

Inspect and test£ºGB/T139271992, API598

Side flange connections£ºGB9115.88, GB9113.3 ~5-88, ASME B16.5CL.150£¬CL.300 and ASME B16.47CL.150.

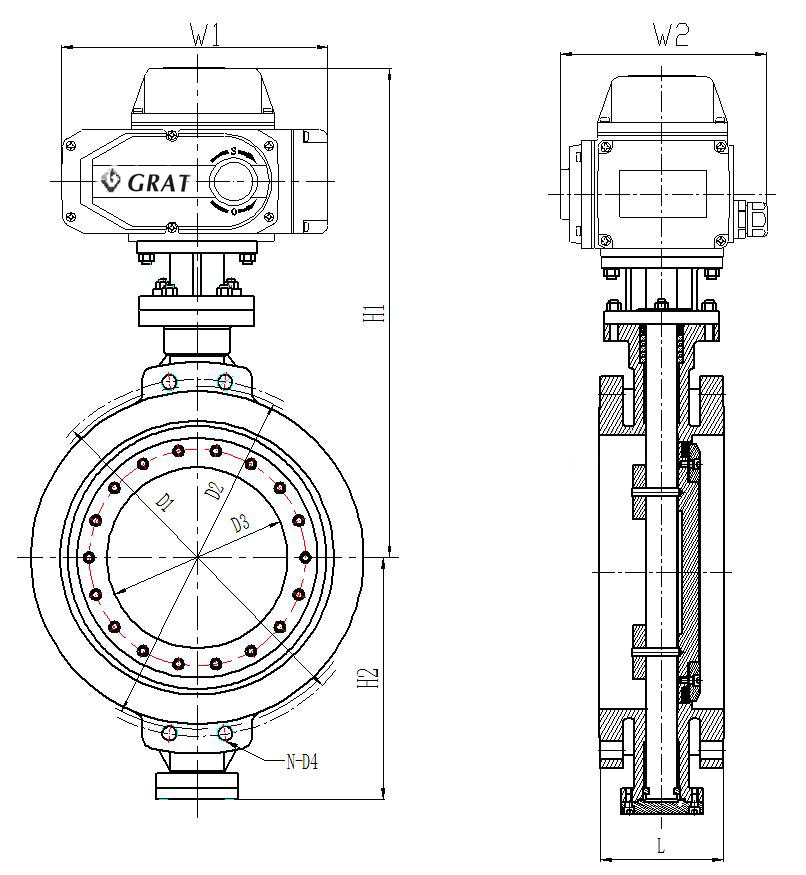

| DN(mm) 1.6Mpa |

D1 | L | D4 | H1 | H2 | W1 | W2 | Weight £¨kg£© |

| 50 | 125 | 43 | φ18 | 112 | 290 | 196 | 145 | 12 |

| 65 | 145 | 46 | φ18 | 115 | 310 | 196 | 145 | 14 |

| 80 | 160 | 49 | φ18 | 120 | 330 | 196 | 145 | 19 |

| 100 | 180 | 56 | φ18 | 138 | 350 | 196 | 145 | 23 |

| 125 | 210 | 64 | φ18 | 164 | 390 | 196 | 145 | 28 |

| 150 | 240 | 76 | φ23 | 175 | 430 | 255 | 184 | 32 |

| 200 | 295 | 89 | M20 | 208 | 490 | 255 | 184 | 54 |

| 250 | 355 | 114 | M24 | 243 | 520 | 255 | 184 | 76 |

| 300 | 410 | 114 | M24 | 283 | 550 | 255 | 184 | 95 |

| 350 | 470 | 127 | M24 | 310 | 600 | 255 | 184 | 130 |

| 400 | 525 | 140 | M27 | 340 | 660 | 354 | 273 | 161 |

| 450 | 585 | 152 | M27 | 380 | 750 | 354 | 273 | 210 |

| 500 | 650 | 152 | M30 | 410 | 800 | 354 | 273 | 250 |

| 600 | 770 | 154 | M33 | 470 | 860 | 354 | 273 | 376 |

| 700 | 840 | 165 | M33 | 550 | 1020 | 354 | 273 | 450 |

| 800 | 950 | 190 | M36 | 640 | 1080 | 354 | 273 | 600 |

| 900 | 1050 | 203 | M36 | 710 | 1150 | 354 | 273 | 732 |

| 1000 | 1170 | 216 | M39 | 770 | 1220 | 354 | 273 | 931 |

| 1200 | 1390 | 254 | M45 | 890 | 1380 | 354 | 273 | 1352 |

|

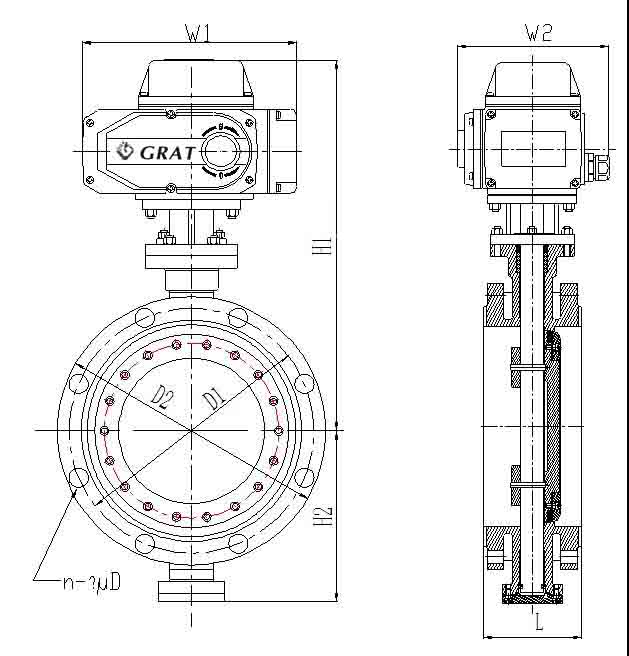

(DN) |

D1 |

D2 |

n-ΦD |

L |

H1 |

H2 |

W1 |

W2 |

Weight |

|

50 |

125 |

165 |

4-Φ18 |

108 |

292 |

112 |

196 |

145 |

20 |

|

65 |

145 |

185 |

4-Φ18 |

112 |

295 |

115 |

196 |

145 |

25 |

|

80 |

160 |

200 |

4-Φ18 |

114 |

300 |

120 |

196 |

145 |

28 |

|

100 |

180 |

220 |

8-Φ18 |

127 |

318 |

138 |

196 |

145 |

32 |

|

125 |

210 |

250 |

8-Φ18 |

140 |

344 |

164 |

196 |

145 |

45 |

|

150 |

240 |

285 |

8-Φ18 |

140 |

425 |

175 |

255 |

184 |

50 |

|

200 |

295 |

340 |

8-Φ22 |

152 |

458 |

208 |

255 |

184 |

70 |

|

250 |

355 |

405 |

12-Φ22 |

165 |

493 |

243 |

255 |

184 |

108 |

|

300 |

410 |

460 |

12-Φ26 |

178 |

533 |

283 |

255 |

184 |

150 |

|

350 |

470 |

520 |

12-Φ26 |

190 |

610 |

310 |

355 |

273 |

190 |

|

400 |

525 |

580 |

16-Φ26 |

216 |

640 |

340 |

355 |

273 |

290 |

|

450 |

585 |

640 |

16-Φ30 |

222 |

680 |

380 |

355 |

273 |

380 |

|

500 |

650 |

710 |

20-Φ30 |

229 |

710 |

410 |

355 |

273 |

460 |

|

500 |

650 |

710 |

20-Φ30 |

229 |

710 |

410 |

355 |

273 |

460 |

|

600 |

749.5 |

813 |

20-Φ36 |

267 |

960 |

450 |

520 |

470 |

660 |

|

700 |

840 |

910 |

24-Φ36 |

292 |

1050 |

550 |

520 |

470 |

750 |

|

800 |

950 |

1025 |

24-Φ39 |

318 |

1150 |

640 |

520 |

470 |

1000 |

|

900 |

1050 |

1125 |

28-Φ39 |

330 |

1220 |

710 |

520 |

470 |

1150 |

|

1000 |

1170 |

1255 |

28-Φ42 |

410 |

1280 |

770 |

520 |

470 |

1500 |

Properties and specification

|

Valve size DN |

50 ~1200 |

50 ~600 |

mm |

||||||

|

Body ratings PN |

0.6 |

1 |

1.6 |

150LB |

2.5 |

4 |

300LB |

Mpa |

|

|

Test properties pressure |

Seal |

0.66 |

1.1 |

1.76 |

2.2 |

2.75 |

4.4 |

5.5 |

|

|

Body |

0.9 |

1.5 |

2.4 |

3 |

3.75 |

6 |

7.5 |

||

|

Applicable temperature |

≤540 |

¡æ |

|||||||

|

Applicable medium |

Water, oil, gas, all kinds medium of high temperature and mixed impurities. |

¡¡ |

|||||||

The material for main parts

|

Item |

Part name |

Material |

|

1 |

Body |

Carbon steel¡¢CF8 Stainless steel¡¢CF8M Stainless steel¡¢CF3M Stainless steel |

|

2 |

Disc |

Carbon steel¡¢CF8 Stainless steel¡¢Cram Stainless steel¡¢CF3M Stainless steel |

|

3 |

Rotatable shaft |

2Cr13¡¢304 Stainless steel¡¢316 Stainless steel¡¢316L Stainless steel |

|

4 |

Disc seal ring |

all kinds of stainless steel composite |

|

5 |

Shaft sleeve |

ZCuZn38Mn2Pb2¡¢stainless steel composite, PTFE |

|

6 |

Packing |

Grafoil |

Pressure and temperature grade

|

Maxi. Temp.¡æ |

≤20 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

425 |

450 |

475 |

500 |

Body material |

|

Body ratings Mpa |

|

||||||||||||

|

0.6 |

0.60 |

0.60 |

0.54 |

0.48 |

0.42 |

0.36 |

0.30 |

0.21 |

---- |

---- |

---- |

---- |

Stainless steel |

|

1.0 |

1.00 |

1.00 |

0.90 |

0.80 |

0.70 |

0.60 |

0.50 |

0.35 |

---- |

---- |

---- |

---- |

|

|

1.6 |

1.60 |

1.60 |

1.44 |

1.28 |

1.12 |

0.96 |

0.80 |

0.56 |

---- |

---- |

---- |

---- |

|

|

2.5 |

2.50 |

2.50 |

2.25 |

2.00 |

1.75 |

1.50 |

1.25 |

0.88 |

---- |

---- |

---- |

---- |

|

|

0.6 |

0.57 |

0.52 |

0.48 |

0.45 |

0.42 |

0.40 |

0.38 |

0.37 |

0.36 |

0.35 |

0.35 |

0.35 |

Carbon Steel |

|

1.0 |

0.95 |

0.86 |

0.81 |

0.76 |

0.71 |

0.66 |

0.63 |

0.61 |

0.60 |

0.59 |

0.58 |

0.58 |

|

|

1.6 |

1.52 |

1.31 |

1.29 |

1.21 |

1.13 |

1.06 |

1.01 |

0.98 |

0.96 |

0.94 |

0.93 |

0.92 |

|

|

2.5 |

2.38 |

2.15 |

2.01 |

1.89 |

1.77 |

1.66 |

1.59 |

1.53 |

1.50 |

1.48 |

1.46 |

1.45 |

|

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...