Classification£º¡¡Electric control valve

Product Name£º¡¡Fluorine Anticorrosive Electric Control valve

Product Description£º

This fluorine electric ball valve is designed to switch and cut off various strong corrosive medium, which is widely applied in petroleum, chemical, pesticide, dye, acid, alkali and so on, and which is the most ideal choice for anti-corrosion equipment at present.

This valve which adopts polytetrafluoroethylene (FEP) as anti-corrosion lining material has very superior anti-corrosion and abrasion resistance. The unique structure for lip type elastic seal parts well extends the service life of the products.

The fluorine butterfly valve, not only transmits medium as common ball valve, but also transmits the liquid such as acid, alkali, salt, mixed liquid containing solid particles and corrosive gas in the situation of a large pressure drops and temperature drops.

The electric actuator with servo system inside accurately controls the valve opening via signal 4~20mA from industrial automation control system, which regulates and controls the different technical parameters of the flow, temperature, pressure.

¡ïBeautiful appearance, compact structure, high strength, zero leakage

This valve with an innovative optimized design by three-dimensional model of CAD has a beautiful and compact appearance and modern modeling, and adopts new material and new technology to ensure that the valve has the good quality, good product performance, more reliable, more economical, more durable, which is fully compliant with the latest technical specifications of international standard, and which is the first choice for future automation system.

With the full-size and floating ball structure, the valve can be shut off without leakage in the whole pressure range, which is convenient to pipeline pigging and maintenance.

The compact and reasonable structure and the minimum space of bore reduce the medium retention. In addition, a special molding process ensures that the sealed surface presents good density, and even the herringbone ring PTFE packing assures the valve of zero leakage.

¡ïStrong corrosion resistance, a broad scope of application

The valve owns excellent corrosion resistance to chemical.

The ball valve with FEP lining has high chemical stability, and is suitable for any strong corrosive medium except the "molten alkali metals and fluorine."

¡ïDiversified performance, suitable for the transmission of mediums with large pressure drops and large temperature drops, convenient to install

The ball body (headstock piece) and stem are cast or forged to a integrated structure together, which eliminates the possibility of the stem impacting to the pressure part caused by the pressure change, and fundamentally guarantees the use safety in project.

The actuator has enough torque, light weight, small volume and convenient installation.The valve owns excellent strength and toughness, abrasion resistance, easy to disassemble, simple to maintain.

The valve has superior corrosion resistance to chemical.

The clean and smooth pipe wall can transmit liquid with small friction resistance and adhesive force.

The valve has the excellent aging resistance and UV resistance, which make the normal service life extend a lot than other pipeline systems.

¡ïThe patent positioning technology

PPD positioning technology completely solves the problem of poor positioning accuracy and a major application difficult of long time reliable operation.

¡ïSimple structure, easy to operate ,high cost-effective.

This fluorine anticorrosion electric control valve with the diversiform plug structure (V type, O type) is easy to realize the regulation and cutting off by two-position. It is direct connection between the valve and actuator.

The electric actuators with servo system inside never need be configured with the servo amplifier, whose operation can be controlled by inputting 4-20mA signal and 220VAC power.

The valve presents simple connection, compact structure, small resistance, stable and reliable action.

The two-piece, three-piece structure can adapt to working conditions and the piping system with different requirements, and of them the three-piece ball valve allows the main body and the both sides bodies to be separated, so as to realize rapid replacement and maintenance online.

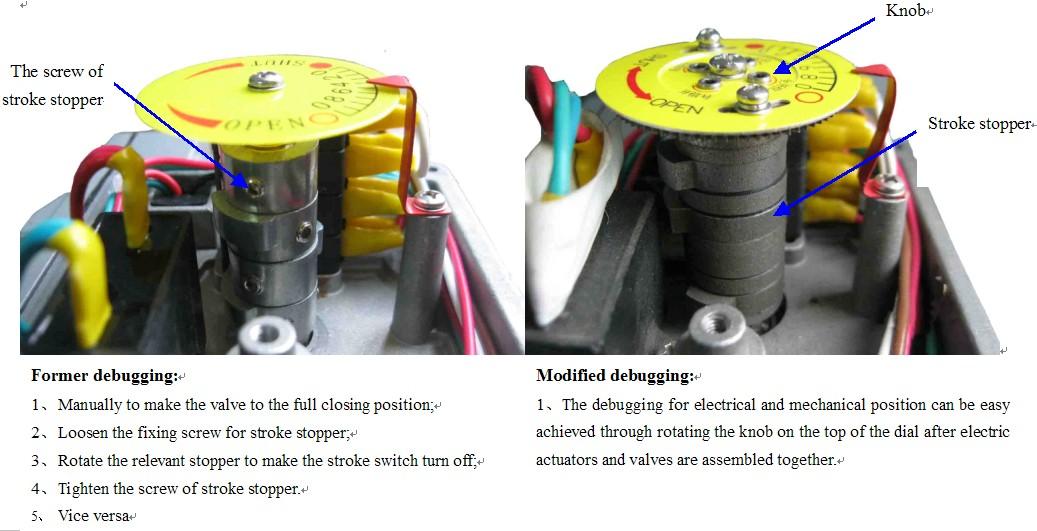

¡ïThe new technology for Direct Debugging Switch(DDS) in electric actuators.

Easy to use! Design by GRAT in China.

It completely solved the problem of complex debugging and make the technology simpler.

The debugging can be simplified from 5 steps to 1 step.

The debugging for electrical and mechanical position can be easy achieved through rotating the knob on the top of the dial after electric actuators and valves are assembled together.

Power supply: AC220V

Body size: DN15-350

Medium Temp. -80¡æ~160¡æ£¨no congelation.£©

Operating pressure: PN1.0¡«2.5(MPa)

Action mode: 4-20mA

Signal input feedback, 0-90° gyration.

Action time: 4~30S

Body connections: Flange

Body material: WCB, ZG1CrM0, ZG1Cr18Ni9Ti

Sealed material: PTFE

Actuator material: Casting aluminum alloy

Applicable medium: Acid, alkali, salt, chlorine gas, steam, source water, mine pulp and paper pulp, aqua regia, oxidant, reducing agent, corrosive chemical liquid.

The compliant standards of the products

Design and manufacturing standards: GB12237-89 AP16D

Flange standards: JB79 GB9113 ANSI B16.5 JIS B2212

Structure length standards: GB1221-89

Inspection standards: JB/T 9092 API598

1. The material of the main parts

| Part name | Body | Bonnet | Stuffing box | Gland ring | Seat | Packing | Spanner |

| Material trademark | WCB ZG1CrM0 ZG 1Cr18Ni9Ti |

WCB ZG1CrM0 ZG 1Cr18Ni9Ti |

WCB 40Cr ZG 1Cr18Ni9Ti |

WCB ZG1CrM0 ZG 1Cr18Ni9Ti |

FEP | FEP | WCB |

2. Applicable channeling medium

| Medium state | Medium Temp. | Medium pressure | Medium characteristics | Medium concentration | Medium name |

| Liquid | -80¡æ~+160¡æ | 0~20kg/cm2 | Strong corrosion, high scour sharpen | Unlimited | Acid, alkali, salt, chlorine, steam, source water, mine pulp, paper pulp, aqua regia, oxidant, reducing agent. |

| Gas | -80¡æ~+160¡æ | 0~20kg/cm2 | Strong corrosion, high scour sharpen | Unlimited | |

| Mixture of liquid and solid | -80¡æ~+160¡æ | 0~20kg/cm2 | Strong corrosion, high scour sharpen | £¼60% |

3. The properties parameters

|

Body ratings |

Strength£¨MPa£© |

Seal£¨MPa£© |

Lining insulation test voltage |

||||

|

1.0 |

1.6 |

2.5 |

1.0 |

1.6 |

2.5 |

||

|

Test pressure value |

1.5 |

1.82 |

2.6 |

1.1 |

1.7 |

2.5 |

20KV |

4. The medium can’t be channelized

Oxygen, hydrogen, natural gas, coal gas, combustible gas, combustion-supporting gas.

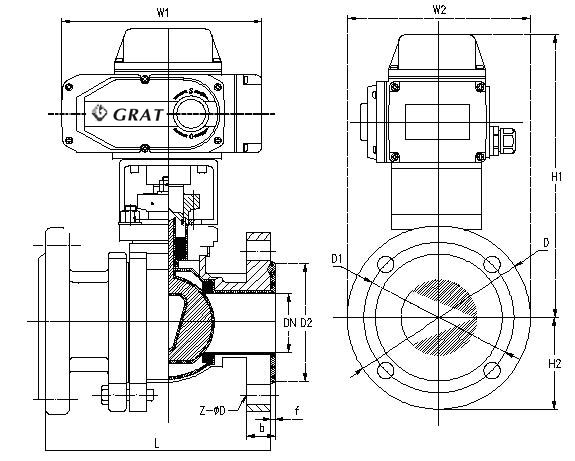

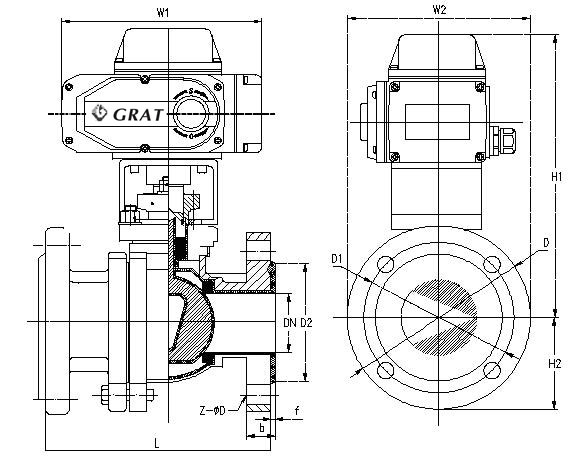

5. Main connection size

| size Mpa DN |

L | D | D1 | D2 | Z-ΦD | f | b | H2 | H1 | W1 | W2 | Weight kg |

|

| 15 | 1.6 | 140 | 95 | 65 | 45 | 4-Φ14 | 2 | 13 | 50 | 250 | 196 | 145 | 5 |

| 20 | 1.6 | 140 | 105 | 75 | 55 | 4-Φ14 | 2 | 13 | 55 | 255 | 196 | 145 | 6.5 |

| 25 | 1.6 | 150 | 115 | 85 | 65 | 4-Φ14 | 2 | 13 | 60 | 260 | 196 | 145 | 7.4 |

| 32 | 1.6 | 165 | 135 | 100 | 78 | 4-Φ18 | 2 | 13 | 70 | 270 | 196 | 145 | 9.8 |

| 40 | 1.6 | 180 | 145 | 110 | 85 | 4-Φ18 | 3 | 14 | 75 | 275 | 196 | 145 | 10.6 |

| 50 | 1.6 | 200 | 160 | 125 | 100 | 4-Φ18 | 3 | 17 | 80 | 280 | 196 | 145 | 12.5 |

| 65 | 1.6 | 220 | 180 | 145 | 120 | 4-Φ18 | 3 | 17 | 90 | 290 | 196 | 145 | 17.9 |

| 80 | 1.6 | 250 | 195 | 160 | 135 | 8-Φ18 | 3 | 18 | 100 | 330 | 255 | 184 | 25.9 |

| 100 | 1.6 | 280 | 215 | 180 | 155 | 8-Φ18 | 3 | 19 | 110 | 340 | 255 | 184 | 33.1 |

| 125 | 1.6 | 320 | 245 | 210 | 185 | 8-Φ18 | 3 | 21 | 125 | 355 | 255 | 184 | 54.6 |

| 150 | 1.6 | 360 | 280 | 240 | 210 | 8-Φ23 | 3 | 23 | 140 | 370 | 255 | 184 | ¡¡ |

| 200 | 1.6 | 400 | 335 | 295 | 265 | 8-Φ23 | 3 | 24 | 170 | 400 | 255 | 184 | ¡¡ |

| 250 | 1.6 | 450 | 390 | 350 | 320 | 12-Φ23 | 3 | 26 | 200 | 485 | 354 | 273 | ¡¡ |

| 300 | 1.6 | 610 | 440 | 400 | 368 | 12-Φ23 | 4 | 28 | 220 | 505 | 354 | 273 | ¡¡ |

| 350 | 1.6 | 686 | 500 | 460 | 428 | 16-Φ23 | 4 | 31 | 250 | 535 | 354 | 273 | ¡¡ |

Electric butterfly valve

Electric butterfly valve Central Line Soft Seat ...

Central Line Soft Seat ...